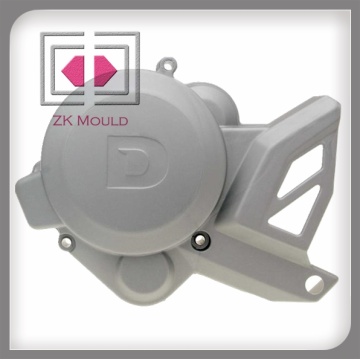

Automobile Aluminum Die Casting Crankcase Cover

| Unit Price: | Get Latest Price |

|---|---|

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

| Port: | Guangzhou Port,Shenzhen Port,Foshan Port |

- Product Catalog

- Company List

Product Description

- Model No.: ZK-0109

- Packaging: Carton + Plastic film + Pallet

- Productivity: 5000 Ton / Year

- Brand Name: Zheke

- Place of Origin: China

- Supply Ability: 5000 Ton / Year

- Certification: ISO9001:2015

- HS Code: 7616991090

This Automobile Aluminum Die Casting Crankcase Cover is suitable for motor vehicle products

The crankcase is the most important part of the engine. It takes the force from the connecting rod and converts it into torque through the crankshaft output and drives other accessories on the engine. The crankshaft is subjected to a centrifugal force of a rotating mass, a cyclically varying gas inertial force, and a reciprocating inertial force to cause the crankshaft to undergo a bending torsional load. Therefore, the crankshaft is required to have sufficient strength and rigidity, and the journal surface needs to be wear-resistant, work evenly, and have good balance.

Zheke Automobile Aluminum Die Casting Crankcase Cover high quality and low price, we can manufacture several motor vehicle parts

Zheke Mould Technology Co., Ltd founded in 2005.

Company's main business is aluminum die casting mould and aluminum die castings products R&D, design, manufacture and sale.

Customers are mainly large lighting companies, automobile parts limited and machinery manufacturing company.

The company's theoretical capacity can reach 5000 tons of aluminum/year.

Zheke Mould Company has been in the mold manufacturing industry for more than 20 years, Die casting industry over 10 years. Has many experienced technical backbone personnel.

Zheke Mould Technology Co., Ltd have four workshops, die casting material die casting machine and mould are the three major elements of die casting production.

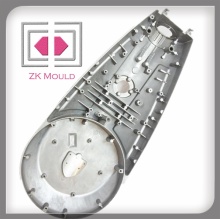

1. Aluminum Die Casting Mould Workshop. It has Radial Drilling Machines, Engine Lathe, Milling Machines, CNC EDM Wire-Cutting Machines, CNC Electric Discharge Machines, Grinding Machines for mould making. We have professional mould designer to design the mould, and we also have our own professional mould making technician team, they strictly follow mould drawing to make mould. They will carry out daily care for the moulds that customers have in our factory.

2. Die Casting Machine Workshop. We have one set hot Chamber Die Casting Machine, eight sets cold Chamber Die Casting Machines, our machine maximum can be done 800T. Before we mass production, we will text mould until customer satisfaction. We have someone to check die casting product on machine production line every day.

3. Machining Workshop. We have Drilling and Tapping Machines, CNC Lathes, CNC Machining Centre, Special Combination Machines, Hydraulic Press, Sawing Machines. We drill in strict accordance with the customer's product drawings. Machining Workshop Supervisor will conduct random sampling every day.

4. Grinding Workshop. We have Belt Polishing Machines, Pneumatic Files, Flat-Grinding Machines. We will grind and remove the edges according to the customer's requirements and product drawings. After the product has been surface treated. We have a special inspection team to carry out the final inspection of each product one by one, to ensure that each product is delivered to the customer is no problem.

1. Aluminum die casting product advantage:

1) Light Weight;

2) Retain high dimensional stability thin walls and complex shapes;

3) Corrosion resistant;

4) Good mechanical properties;

5) Has the bearing capacity in as wide range of temperatures;

6) High thermal and electrical conductivity;

7) Finishing has smooth surface.

2. Our company advantage:

1) We have good sales team and technical team;

2) Product quality assurance;

3) We give you from pre-sales to after-sale services;

4) We provide die-casting aluminum service;

5) We making worth by heart;

China

Min. Order:3

China

Min. Order:1

Min. Order:1

Foshan Zheke Mould Technology Co,. Ltd founded in 2005, and locate in Pearl River Delta Foshan city economic famous town--Shishan Town.

Company`s main business is aluminum die casting mould and aluminum die casting products R&D, design, manufacture and sale. Customers are mainly large lighting companies, automobile parts limited and machinery manufacturing company.

Zheke Mould company`s predecessor is called Yongke Mould company, because of the increasing economies of scale, so Zheke mould company removal the bigger workshop and change the name.

Since the development of the company, there have been a major production six sets of CNC equipment, eight sets of cold chamber die casting machine, the maximum tonnage is 800 tons. There are other mould manufacturing equipment and die-casting post-processing equipment. The company's theoretical capacity can reach 5000 tons of aluminum/year.

Zheke Mould Company has been in the mold manufacturing industry for more than 20 years, Die casting industry over 10 years. Has many experienced technical backbone personnel.

Basic Information

- Company Name:

Zheke Mould Technology Co. Ltd.

- Representative:

Chen Zixuan

- Business Type:

Manufacturer , Retailer

- Product/Service:

Aluminum Die Casting , CNC Metal Machining , Die-Casting Mould , OEM Die Casting , OEM Aluminum Die Casting Mould , Aluminum Die Casting Parts

- No. of Total Employees:

101~200

- Capital (Million US $):

1 Million

- Year Established:

2005

- Product Range:

Machining Services , Moulds , Die Casting Machine

- Certificate:

Manufacturer , Retailer

- Company Address:

Boai&Hongling rd, Shishan Town,Nanhai

Trade & Market

- Total Annual Sales Volume (Million US $):

US$2.5 Million - US$5 Million

- Export Percentage:

31% - 40%

- Total Annual Purchase Volume (Million US $):

US$1 Million - US$2.5 Million

- Main Markets:

Americas , Asia , Europe , North Europe , West Europe , Africa , East Europe , Middle East

Factory Information

- No. of Production Lines:

8

- No. of R&D Staff:

91 -100 People

- No. of QC Staff:

11 -20 People

- OEM Services Provided:

yes

- Factory Size (Sq.meters):

1,000-3,000 square meters

- Factory Location:

Boai&Hongling rd, Shishan Town,Nanhai

Other products from this company MoreEmail to this supplier

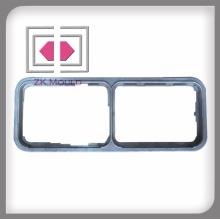

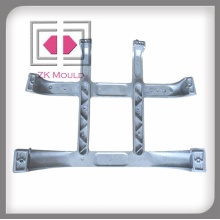

Categories: Other Automobile Aluminum Die Casting Part

Business type:Manufacturer,Retailer

Certification:ISO9001OEM service:yes

Our Products Range