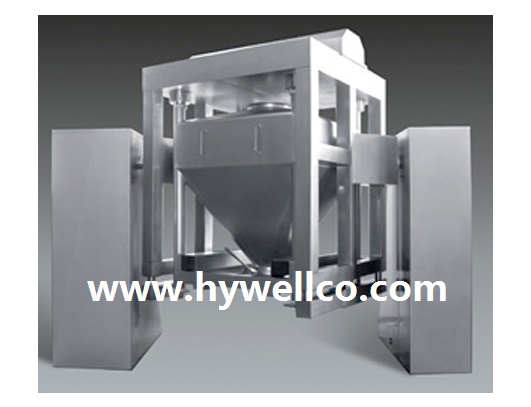

FZH Series Hopper Mixer

| Unit Price: | USD 5000 / Set/Sets |

|---|---|

| Unit Price: | 5000.0000 USD |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Shanghai |

- Product Catalog

- Company List

Product Description

- Model No.: FZH

- Packaging: Wood Box

- Productivity: 20-30 Set per Year

- Brand Name: Erbang

- Place of Origin: China

- Supply Ability: 5 Set/Sets per Month

- Certification: ISO

- HS Code: 8479820090

FZH Series Hopper Mixer

FZH Series Hopper Mixer Features:

1. To ensure the quality of the FZH Series Hopper Mixing Machine, Erbang Drying adopt high quality out purchased parts for this FZH Series Hopper Mixing Machine.

3. Erbang supply series product for material conveying. It forms advanced process together with the hopper mixing machine.

4. FZH Series Hopper Blender is novel in design and has compact structure and nice appearance. The evenness of mixing achieves above 99% and the volume charge coefficient reaches 0.8.

5. The system controlled by PLC, sensor of photoelectric position control, and drive system which composed of motors, thus, can control the mixing time and unloading position. And when machine stopped, the discharge port will at the best position for unloading.

6. The locking clamp structure of loading cover bolt is easy for disassembly, cleaning and well sealing, and no leakage found in testing fill with water cover 80% of total volume.

7. Silicon soft connecting is used for connecting between inlet/outlet of the bin and other equipment, thereby, avoids flying dust.

FZH Series Hopper Mixer is ideal for powder and granules mixing applications in foodstuff industry with high mixing efficiency and without cross contamination and dust. Thus, the FZH Series Hopper Mixer can satisfy strict batch control and comply entirely with GMP requirements for medicine production.

This FZH Series Hopper Mixing Machine can catch several kinds and different sizes of bins, which lifting, clamping, mixing, descending and clamp losing full automatically. One main machine can be configured with various bin specifications, thus it's the ideal blender for general mixing in pharmaceutical plant, meanwhile, widely used in chemical, light and food industries, etc.

Working Principle

FZH Series Hopper Blender is composed of frame, clamping type of rigid rotating shell (hereinafter called "rotating shell"), lift descend /clamp, drive, brake and control systems.

When start working, firstly, put the loaded square mixing bin (hereinafter called "bin") into rotating shell and a position signal will be sent by the control system when the bin fixed position. Press "confirm" key on the touch panel, the bin will be automatically raised in position and clamped by the lift descend /clamp system. After the bin fully clamped, the drive system starts blending according to the setting time and rotating speed. On achieving the set mixing time, the rotating shell slow down automatically, and brake system operates to stop the rotating shell vertically for moving the bin out easily and the blending task finished. Then the lift descend /clamp system work to lower the bin on the ground. Meanwhile, the printer will print out complete data of this batch. Finally, move out the bin from rotating shell and thus finish this blending cycle.

welcome to inquiry Erbang Drying!

| Model | FZH400 | FZH600 | FZH800 | FZH1000 | FZH1500 |

| Max charge (L) | 320 | 480 | 640 | 800 | 1200 |

| Max charge (kg) | 160 | 240 | 320 | 400 | 600 |

| Power | 4.75 | 7 | 7 | 8.5 | 10.5 |

| Machine size | 2460X2410X3200 | 2950X2860X3200 | 2950x2860x3500 | 3150×3030×3350 | 3260×3200×3650 |

| Machine weight | 1800 | 2500 | 2600 | 3000 | 3700 |

About Us:

Erbang Drying is a professional manufacturer of industrial drying machine, mixing machine and granulating machine. Our flagship products include the hot air dryer, vibration fluid bed dryer, belt dryer, vacuum dryer, one dimensional mixer, two dimensional mixer, three dimensional mixer, and high speed granulator and so on. These high-performance machines have extensive applications within industries such as food, medicine and chemical. Sustained development and a strong emphasis on research and technology have bolstered our quality standards. we seek to achieve the highest level of customer satisfaction through professionally developed drying ,mixing and granulating solutions. Erbang Drying constant faith is providing perfect products to customer, excellenting service to customer !

Quality control

In order to ensure quality of product, we focus on user 's requirements and control improvement and enhancement quality of products .The quality assurance mainly focus on the processes of ensuring production readiness inspection, control of raw materials and components, process control, critical parts, important parts of quality control, assembly quality control, process control testing, measurement equipment control. Pay close attention to the implementation of the quality assurance work, strictly to three inspection system of self-checking, mutual inspection, special inspection. The key point of Quality assurance is focuses on critical parts, important parts of quality control, the quality standards required by ISO9000 quality control procurement documents in order to clarify its status and acceptance of quality standards for company's re-inspections ; For critical parts and important that the key processes of identification and corresponding technical documentation, control by "the implementation of key quality control process", and complete, accurate and complete original records. Difficulties in quality assurance is a special process control, quality assurance is mainly painting, has developed a special process (painting) process documents, take the appropriate technical measures, to quality assurance.

In the production process, we pay close attention to quality control of each process. Every component, every process was strictly controlled. Enhanced the quality inspection process, the establishment of the necessary quality control point, the process by a full-time staff and quality inspector for inspection and supervision. Improved testing procedures and operating instruction.

OUR SERVICES

Pre-sale service

We Invite customers to visit our company and communicate on technical requirements face to face.

Sale service

Responsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging, maintenance, training and other services (Optional); Provide relevant technical data, equipment, software and related GMP certification materials;Set up after-sales service hotline.

Quality promise

Our company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality. Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year, all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage, our company offer free maintenance or replacement.

Shandong,China

Min. Order:1ton

About Us

Changzhou Erbang Drying Equipment Co., Ltd. is a market leader in providing solutions for small and medium-sized trial production lines of ternary precursors, and a leading manufacturer of one-stop pharmaceutical equipment solutions. The main products of Erbang Drying include reaction kettle, pan dryer, fluidized bed dryer, paddle dryer, spray dryer, flash dryer, vacuum dryer, boiling dryer, high-speed mixer, etc.

Erbang Drying customizes the design for your project based on your process and layout requirements. As a process equipment, we have solved many process problems for our customers in the past 20 years.

Erbang Drying realizes that application is key, which is why we focus on integrating processes and machinery to solve your process problems.

Professional knowledge of the production process from laboratory to product definition. Erbang Drying also has laboratory machinery, including laboratory reaction kettle, laboratory powder mixer and spray dryer.

Erbang Drying has various special ternary precursor pilot production lines and lithium iron phosphate dryer production lines. Your process takes into account innovative technologies for special applications.

Erbang drying can improve process testing services and provide you with the best equipment selection. Customize and design the best equipment that meets your process requirements. Because only those who understand the process and details can develop products that are not just the sum of individual components. Erbang Drying provides support in the fields of new energy, pharmaceuticals, health products, food, fine chemicals, and feed processing through our international innovative process solutions.

Erbang Drying customizes all equipment related documents to make training, operation, and maintenance of equipment throughout its entire lifecycle easier, even in more urgent industries such as the pharmaceutical market. We provide a complete set of GMP documents, including qualifications (DQ IQ、OQ)、FAT、SAT、 User manual document. We carry out qualification certification according to customer requirements.

Our business department operates under strict international quality standards and has obtained the ISO9001 control regulation certificate, which is known as the 'International Quality Certification'.

Machine manufacturing is a highly competitive industry that requires continuous improvement in productivity and cost reduction.

Erbang Drying is committed to becoming a top pharmaceutical equipment manufacturer and supplier.

We are passionate about our business and constantly push the limits of our professional knowledge to provide high-quality and innovative solutions for reaction vessels, drying, mixing, and granulation for numerous international brands.

Welcome to visit the factory anytime!

The current situation and prospects of Erbang drying

Erbang Drying Company. We are a professional manufacturer of reaction vessels, drying, mixing, crushing, and granulation systems. Our most advanced and proprietary technology in this field comes from China; With the advantage of low labor costs in China, Erbang Drying will become your partner for cost-effective solutions in ternary precursor reaction vessels, drying systems, powder mixing, and powder granulation.

Erbang Drying Product Series

Erbang Drying not only provides modern and technologically advanced standalone equipment, but also offers a complete production line system to save your time, which is one of our advantages. With decades of experience as engineers in this field, Erbang Drying can provide the most suitable solution for any industry that requires reaction vessels, drying, mixing, crushing, and granulation systems.

We are so successful because we focus on sustainable development through excellent engineering technology. Our equipment has been carefully designed to provide excellent performance not only in current applications, but also in future applications. We know that flexibility and adaptability are key to creating sustainable businesses, as are excellent customer service, support, and technology.

Basic Information

- Company Name:

Changzhou ErBang Drying Equipment Co., Ltd.

- Representative:

Cha xinbao

- Business Type:

Manufacturer

- Product/Service:

Ternary material reactor , Drying Machine , Granulating Machine , Grinding Machine , Mixing Machine , Coating Machine

- No. of Total Employees:

51~100

- Capital (Million US $):

12880000RMB

- Year Established:

2007

- Product Range:

Reactors , Filling Machines , Bag Making Machines

- Certificate:

Manufacturer

- Company Address:

Wugang Industrial Park, Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Trade & Market

- Total Annual Sales Volume (Million US $):

Above US$100 Million

- Export Percentage:

21% - 30%

- Total Annual Purchase Volume (Million US $):

Below US$1 Million

- Main Markets:

Americas , Asia , Europe , North Europe , West Europe , East Europe , Middle East , Oceania , Other Markets

Factory Information

- No. of Production Lines:

10

- No. of R&D Staff:

11 -20 People

- No. of QC Staff:

Fewer than 5 People

- OEM Services Provided:

YES

- Factory Size (Sq.meters):

5,000-10,000 square meters

- Factory Location:

Wugang Industrial Park, Zhenglu Town, Tianning District, Changzhou City, Jiangsu Province, China

Other products from this company More

Categories: Granules Mixing Machine

Business type:Manufacturer

Certification:CE,ISO9001OEM service:YES

Our Products Range