Hemicellulase enzyme for baking juice feed oil drilling

| Unit Price: | USD 39 / Kilogram |

|---|---|

| Unit Price: | 39 USD |

| Min. Order: | 100 Kilogram |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Shanghai,Guangzhou |

- Product Catalog

- Company List

Product Description

- Model No.: Food grade Hemicelllulase

- place of origin: China

- Types of: Enzyme Preparations

- Packaging: 1KG;25KG

- Productivity: 10000T/MONTH

- Brand Name: SUNSON

- Place of Origin: China

- Supply Ability: 10000T/MONTH

- Certification: ISO22000;MUI,FAMI-QS;NON-GMO;FSSC22000;KOSHER;HALAL

- HS Code: 3507909090

PRODUCT DESCRIPTION

This product is produced by submerged fermentation of a traditionally selected Bacillus lentus strain followed by purification, formulation and drying. The product contains variety of activities targeting at hemicellulose, an important part of plant cell wall. The product is used effectively in food, plant extract, feed, textile, pulp & paper, and even petrol oil drilling.

MECHANISM

Hemicellulose comprises heterogenous polysaccharides made up of hexose, pentose and their derivatives, notably xylose and mannose. The multi-component hemicellulase is able to degrade different hemicellulose polymers to produce oligomers and their building blocks. Since hemicellulose makes big part of plant cell wall, and usually presents viscosity problem when released into solution, their degradation leads to disruption of plant cells, liberation of cell inclusions and reduction in viscosity during wet processing of plant materials.

APPLICATIONS

-

Fruit and vegetable processing: Used together with pectinase and cellulase for juice yield improvement and juice clarification;

-

Coffee: Increases extraction yield of coffee;

-

Edible oil extraction: Increases oil yield by enzymatic pretreatment;

-

Feed: Improves biological value and utilization of feed by removal anti-nutritional components in feed.

-

Petrol oil drilling: Used as an enzymatic breaker to degrade biological mannan containing thickening agent like guar gum, xanthan gum, konjac gum, etc., reducing the environmental pollution by fracturing liquid;

-

Pulp & Paper: Bleaches pulp by degrading hemicellulose and reduce the use of chemicals.

REACTION PARAMETERS

|

CONDITION |

RANGE |

|

Activity Temperature |

30℃-70℃ |

|

Optimum Temperature |

40℃-55℃ |

|

Activity pH |

3.0-6.5 |

|

Optimum pH |

3.5-5.0 |

PRODUCT STANDARD

The product complies with GB1886.174.

|

No. |

ITEMS |

INDEX |

|

|

1 |

Particle size (%<40 mesh) |

≥80 |

|

|

2 |

≤8.0 |

||

|

3 |

Lead/(mg/kg) |

≤5.0 |

|

|

4 |

Arsenic/(mg/kg) |

≤3.0 |

|

|

5 |

Total viable count/(CFU/g) |

≤50000 |

|

|

6 |

Coliform Bacteria/(CFU/g) |

≤30 |

|

|

7 |

Escherichia coli |

(CFU/g) |

<10 |

|

(MPN/g) |

≤3.0 |

||

|

8 |

Salmonella/(25g) |

Not Detected |

|

PRODUCT SPECIFICATION

Light yellow powder. Color may vary from batch to batch. Color intensity is not an indication of enzyme activity.

APPLICATION RECOMMENDATION

The recommended dosage is 0.01-1.0%/t DS. The dosage has to be optimized based on each application, the raw material specifications, product expectation and processing parameters. It is better to begin the test with the convenient volume.

SAFE HANDLING PRECAUTIONS

Enzyme preparations are proteins that may induce sensitization and cause allergic type of symptoms in susceptible individuals. Prolonged contact may cause minor irritation for skin, eyes or nasal mucosa. Any direct contact with human body should be avoided. If irritation or allergic response for skin or eyes develops, please consult a doctor.

WARNINGS

Keep sealed after use every time to avoid microbial infections and inactivation of enzymes until its finish.

PACKAGE AND STORAGE

Ø Package: 25kg/drum.

Ø Storage: Keep sealed in a dry and cool place and avoid direct sunlight.

Ø Shelf life: 12 months in a dry and cool place.

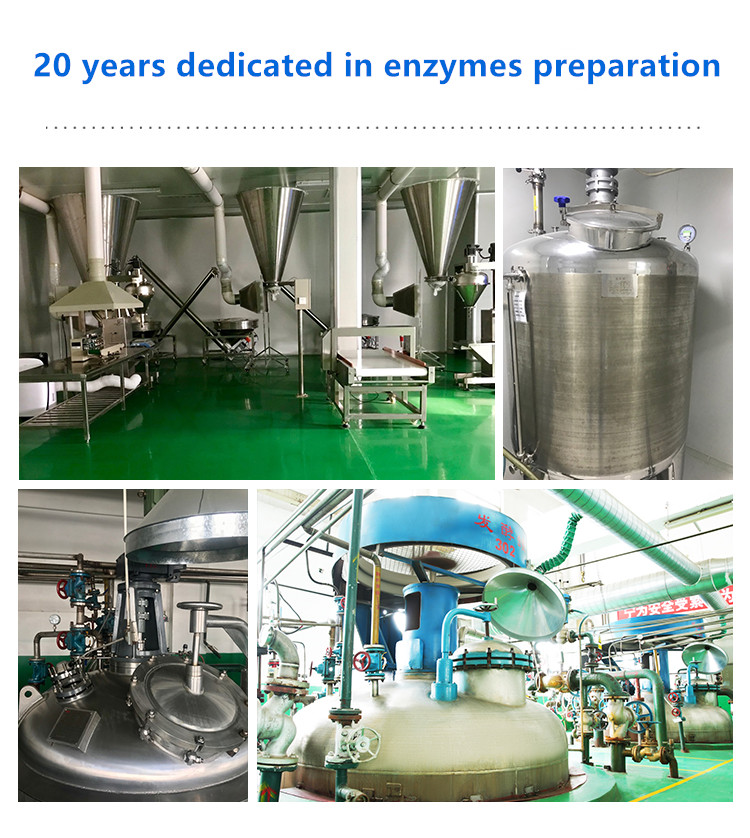

SUNSON Industry Group Co., Ltd was established in 1996 and was the first local company to produce cellulase by submerged fermentation in China. SUNSON Group is a full functioning enzyme company covering R&D, production and sales. It has 9 business divisions,1 Strain R&D Center and 1 Application Technology Center, 1 Technical Service Center and 1 Production Technology Center. The company has built 2 modern production factories with submerged fermentation and ultrafiltration extraction biotechnology. With more than twenty years progress, Sunson has successfully developed series of industrial enzyme products, widely applied in food, brewing, baking, starch sugar, alcohol, juice and wine, plant Extract, fermentation, feed, leather, textile, detergent, and so on. Sunson has become a famous brand in enzyme field by its remarkable R&D capability, production capacity and outstanding enzyme products.

SUNSON is the member of China Biotech Fermentation Industry Association (CBFIA), and member of Enzyme Preparation Branch of CBFIA. SUNSON was honored as the Key Enterprise of China Enzyme Industry by China Fermentation Industry Association, and was the first enzyme manufacturer certified with ISO 22000 Food Safety Management System in China. It was also certified with KOSHER and HALAL, ECOCERT Organic Farming Europe, FSSC22000 Food Safety Management System, ISO9001 Quality Management System and FAMI-QS. Sunson`s products have been exported to more than 30 countries or regions and wide accepted by our customers worldwide.

With the aim to be the world first class enzyme company, Sunson will continue to make great efforts and devote to the sustainable development in the field of enzyme.

Basic Information

- Company Name:

Sunson Industry Group Co., Ltd

- Representative:

Zhongping Du

- Business Type:

Manufacturer , Trade Company , Service

- Product/Service:

Food Enzymes , Animal Feed Enzymes , Baking Enzymes , Textile Enzymes , Leather Enzymes , Detergent Enzymes

- No. of Total Employees:

201~500

- Capital (Million US $):

21,000,000RMB

- Year Established:

1996

- Product Range:

Feed Additives , Food Additives , Detergent

- Certificate:

Manufacturer , Trade Company , Service

- Company Address:

Suite 2302, Zhong'an Shengye Dasha, No. 168, Beiyuan Road, Chaoyang District

Trade & Market

- Total Annual Sales Volume (Million US $):

US$10 Million - US$50 Million

- Export Percentage:

31% - 40%

- Total Annual Purchase Volume (Million US $):

Below US$1 Million

- Main Markets:

Americas , Asia , Europe , North Europe , West Europe , Africa , Caribbean , East Europe , Middle East , Oceania , Worldwide , Other Markets

Factory Information

- No. of Production Lines:

5

- No. of R&D Staff:

31 -40 People

- No. of QC Staff:

11 -20 People

- OEM Services Provided:

yes

- Factory Size (Sq.meters):

10,000-30,000 square meters

- Factory Location:

Cangzhou city, Hebei province, China

Categories: Single Enzymes

Business type:Manufacturer,Trade Company,Service

Certification:ISO9001,FAMI-QS,HACCP,MSDS,ISO22000,GB,Test Report,GMPOEM service:yes

Our Products Range