High Transparent Plastic PETG Sheet for Thermoforming

| Unit Price: | Get Latest Price |

|---|---|

| Payment Type: | T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Delivery Time: | 15 Days |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Shenzhen |

- Product Catalog

- Company List

Product Description

- Model No.: XYH-PETG

- Packaging: 1. Regular packing, protected by pallet. 2. Depending on the requirement of buyers.

- Brand Name: XYH

- Place of Origin: Shenzhen China

- Supply Ability: 100 tons per month

- Certification: SGS,ISO9001

The main characteristics of PETG

· Excellent thermoforming performance

PETG sheet is easy to produce products with complex shapes and large draw ratios. Unlike PC board and impact-modified acrylic, this board does not require pre-drying before thermoforming. Compared with PC board or acrylic, its molding cycle is shorter, the temperature is lower, and the yield is higher.

· Toughness

The extruded sheet of PETG sheet is generally 15 to 20 times tougher than general-purpose acrylic and 5 to 10 times tougher than impact-resistant acrylic. PETG sheet has sufficient bearing capacity during processing, transportation and use, and is not easy to crack.

· Weather resistance

PETG sheet provides weather resistance. It keeps the product tough and prevents yellowing. It contains a UV absorber that can be co-extruded into a protective layer that protects the board from the harmful effects of UV rays.

· Easy processing

PETG sheet can be sawed, die-cut, drilled, punched, cut, riveted, milled and cold-formed without breaking. Slight scratches on the surface can be removed with a hot air gun. Solvent bonding is also a routine operation. It is easier to process than general-purpose acrylic, impact modified acrylic or PC board, and can be processed by flocking, electroplating, static electricity and so on.

· Chemical resistance

PETG sheet can withstand many chemicals and commonly used cleaning agents.

· Environmental protection

PETG board substrates are all environmentally friendly materials and meet food contact management requirements.

POM Sheet;POM Rod;

PTFE Sheet;PTFE Rod;PTFE Cloth

3240 Epoxy Glass Sheet;FR4 Sheet

PA6 Sheet;PA6 Rod;MC Nylon Sheet;MC Nylon Rod

PVC Sheet;PVC Rod;PVC Rod

ABS Sheet;ABS Rod

PEEK;Mica;PE,PP;PU,,PC

China

Min. Order:100

China

Min. Order:100

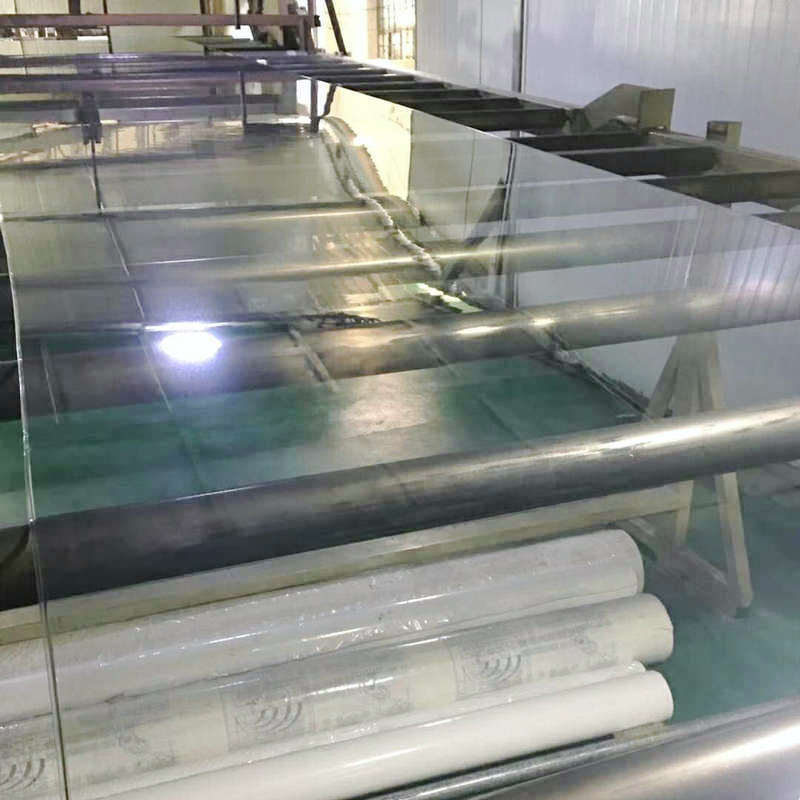

Shenzhen Xiongyihua Plastic Insulation Limited was established in 2006 in Shenzhen, is a manufacturer and trader, specialized in the research, development and production of Engineering Plastic and Insulation Plastic, such as phenolic laminated, epoxy fiberglass, durostone, nylon PA6, POM, PE, PVC. PU, PTFE and ABS.

We also have processing equipment, like CNC carving machines and laser engraving machines for engraving, cutting, bending, and drilling. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. As a result of our products and outstanding customer service, we have gained a global sales network reaching India, Vietnam, Thailand, Indonesia, Philippines, Malaysia, Turkey, Pakistan, Dubai, and some other countries from Europe, like Britain, France, and Germany. And America, Australia, etc. For the past 15 years, XiongYiHua has built its reputation by producing quality products to serve in the after-market, distribution. The company also recognizes the importance of establishing close partnerships with its customers.

One of Top 10 Plastic Insulation manufactures in China Mainland, specializing in plastic extrusion, casting, injection molding etc.

54 production lines for Rod.

17 production lines for sheet.

CNC: 5 sets, lathe: 5 sets, Driller: 3 sets, Grinder: 2 sets, Cutting machine:2 sets.

Established long term relationships in Europe, USA, South America, South Asia etc., and enjoying a great reputation in plastic industry.Basic Information

- Company Name:

SHENZHEN XIONGYIHUA PLASTIC INSULATION LTD

- Representative:

CaiKun Wu

- Business Type:

Manufacturer , Distributor/Wholesaler

- Product/Service:

POM SHEET , FR4 Sheet , Nylon Sheet , Bakelite Sheet , ABS Sheet , PTFE Sheet

- No. of Total Employees:

51~100

- Capital (Million US $):

10000000RMB

- Year Established:

2006

- Product Range:

Insulation Materials & Elements , Plastic Rods , Plastic Sheets

- Certificate:

Manufacturer , Distributor/Wholesaler

- Company Address:

NO.2 Longxian Road,Xinsheng Community,Longgang Street,Longgang District, Shenzhen,Guangdong,China

Trade & Market

- Total Annual Sales Volume (Million US $):

US$10 Million - US$50 Million

- Export Percentage:

71% - 80%

- Total Annual Purchase Volume (Million US $):

US$1 Million - US$2.5 Million

- Main Markets:

Americas , Asia , Europe , North Europe , West Europe , Africa , East Europe , Middle East , Oceania , Worldwide , Other Markets

Factory Information

- No. of Production Lines:

10

- No. of R&D Staff:

5 -10 People

- No. of QC Staff:

5 -10 People

- OEM Services Provided:

yes

- Factory Size (Sq.meters):

5,000-10,000 square meters

- Factory Location:

NO.2 Longxian Road,Xinsheng Community,Longgang Street,Longgang District, Shenzhen,Guangdong,China

Other products from this company MoreEmail to this supplier

Categories: CNC Processing Product

Business type:Manufacturer,Distributor/Wholesaler

Certification:CE,FDA,ISO14001,ISO9001,REACH,RoHS,FCC,MSDS,Test Report,TUVOEM service:yes

Our Products Range