how to fix a wet switch device

| Unit Price: | | Get Latest Price |

|---|

- Product Catalog

- Company List

Product Description

How to fix a wet switch?

If a switch has gotten wet, it is important to act quickly to prevent damage or potential electrical hazards. Here are some steps you can take to fix a wet switch:

1. Turn off the power: Before doing anything, make sure to turn off the power to the switch at the circuit breaker or fuse box to avoid the risk of electric shock.

2. Remove the switch cover: Use a screwdriver to carefully remove the cover plate of the switch to access the internal components.

3. Dry the switch: Use a clean, dry cloth to gently wipe down the switch and remove any excess moisture. You can also use a hairdryer on a low heat setting to help speed up the drying process.

4. Inspect for damage: Check for any signs of corrosion, rust, or other damage that may have occurred due to the water exposure. If the switch appears to be damaged, it may need to be replaced.

5. Test the switch: Once the switch is completely dry, turn the power back on and test the switch to ensure it is functioning properly. If the switch is still not working, it may need to be replaced.

6. Seal the switch: To prevent future water damage, consider using a waterproof switch cover or sealant around the edges of the switch plate to help keep moisture out.

If you are unsure about how to safely fix a wet switch, it is always best to contact a professional electrician for assistance

More services we offer:

Besides of Universal Internet Alarm Communicator ,Metal Stamping components, we also complete solution for OEM/ODM products & components, such as wet switch ,disconnect boxes,float switch etc. offer services of deep drawing services, EMI metal shielding parts, heat sink plastic molding products for custom, plastic injection components, Metal Stamping Parts, home appliances accessories ,R/C drone and smart electronic toys etc.

Our advanced equipments, professional engineers ,high quality system, enable us to provide high quality with low production cost Based on our strength, passion and capacity, we devote to supply one-stop service to customers.

Wish to have an opportunity to cooperate with you in the coming days.

Timeplex group is a Hong Kong based organization with integrated manufacturing facilities in China. Established in 1989, Timeplex brought the Hong Kong management system to meet international standard, along side with years of proven technique and experience.

Timeplex provides customer with complete development capabilities starting from product concept, prototypes to feasibility samples and volume manufacture. Product range including metallic, plastic, electrical and electronics. Our engineering team help clients to develop the product to meet stringent specifications and to compile with the necessary mandatory standards.

Through the effort in the past two decades, Timeplex has become one of the operations who can continuously stand behind its high quality, innovation, affordable pricing and flexible lead time that clients need to remain competitive in the market.

MAIN PRODUCT LINE :

Metallic components may be designed from various materials, PVC conduit fittings,steel, copper, brass, aluminium, tin and lead alloys in sheets,heatsink,EMI/RFI shielding metal case, rolls, rods or ingots

Components in different sizes and configurations may be produced by stamping, forming. extrusion, forging, die-casting and secondary operation such as punching, deep drawing, drilling, threading, and riveting.

For outside appearance and environmental protection, components usually require surface finishing in electro-plating (chrome, nickel, copper, silver or gold), anodizing or powder coating.

In some cases when it is difficult to use metal stamping components to achieve the required configuration, such as piping, curvature or threading, plastic injection parts is a better option. Development of plastic products or part starts from an injection mold. Choice of plastic resins will be the first consideration our engineers will suggest to the client. From the most suitable material such as ABS, PS, PE, PP, PVC, PC etc, and based on customer target production rate and the investment budget, the mold design will be determined and fabrication will start.

Components and parts coming out of the injection molding machine will be relatively uniform. Many of them could replace more than one metallic part or even become a finished product by itself.

Major customers Include : DiversiTech,Sky TV. Walmart, Osram, Hasbro, Intermec, PPG, Fender, Q.A. Smith, Delta, Vtouch, East West, B.A.G., Electrolux

We specialize in the below businesses for you :

1.Metal stamping parts,EMI shielding can,heat sink.

2.Plastic injection components,all kinds PVC fittings,PVC connectors.

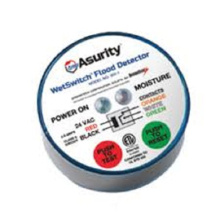

3.Wet switch ,float switch ,Disconnect boxes,Various finished goods assembly.

4.OEM/ODM services ,such as customized disconnect box,wet switch,float switch,inverter,STEAM products and so on.

Looing forward to your coming and get Win-Win in the coming days !

Basic Information

- Company Name:

Timeplex Industrial Limited

- Representative:

Li Hong Gao

- Business Type:

Manufacturer

- Product/Service:

PVC conduit fittings , Metal stamping components , Metal stamping , Plastic injection components , Float switch , Wet switch

- No. of Total Employees:

201~500

- Capital (Million US $):

5,000,000

- Year Established:

1989

- Product Range:

Sheet Metal Fabrication , Plastic Extruders , Ride On Car

- Certificate:

Manufacturer

- Company Address:

No.6 Fukang Road,Shang Sha Community,Chang An Town,Dongguan City,Guangdong Province,China

Trade & Market

- Total Annual Sales Volume (Million US $):

US$10 Million - US$50 Million

- Export Percentage:

91% - 100%

- Total Annual Purchase Volume (Million US $):

US$5 Million - US$10 Million

- Main Markets:

Americas , Asia , Europe , Worldwide

Factory Information

- No. of Production Lines:

above 10

- No. of R&D Staff:

5 -10 People

- No. of QC Staff:

21 -30 People

- OEM Services Provided:

YES

- Factory Size (Sq.meters):

10,000-30,000 square meters

- Factory Location:

No.6 Fukang Road,Shang Sha Community,Chang An Town,Dongguan City,Guangdong Province ,China

Categories: OEM/ODM Products

Business type:Manufacturer

Certification:ISO14001,ISO9001,OHSAS18001,CCC,ULOEM service:YES

Our Products Range