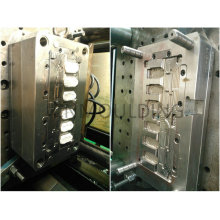

plastic elbow injection mold

| Unit Price: | Get Latest Price |

|---|

- Product Catalog

- Company List

Product Description

- Model No.: CNMOULDING-024

What is core pull injection molding?

Most of you probably have heard of the option “Core Pull” with Injection Molding Machines. Simply put, core pull allows a cavity to be put in the product parallel to the clamp. ... The important component is that the product being create must need a place devoid of plastic that cannot be accommodated by the mold itself.

Molds, various molds and tools used in industrial production to obtain required parts by injection molding, blow molding, extrusion, die-casting or forging molding, smelting, stamping and other methods. In short, a mold is a tool used to make molded objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article by changing the physical state of the formed material. At present, the injection mold has become a very common mold used in the industrial production process. The slider is a mold component that can slide perpendicular to the mold opening direction or at a certain angle to the mold opening direction during the mold opening action. For some Parts with undercuts are often demoulded normally only by adopting a slider structure. But when the molded product is an arc-shaped hollow product, arc core-pulling molding is required

Basic Information

- Company Name:

cnmoulding

- Product/Service:

plastic injection mold &molding

- No. of Total Employees:

51~100

- Year Established:

1997

- Product Range:

Injection Molding Machine

- Company Address:

jiaxin

Trade & Market

- Total Annual Sales Volume (Million US $):

3000000-5000000

- Main Markets:

Americas , Asia , East Europe , Middle East

Factory Information

- No. of R&D Staff:

19

- No. of QC Staff:

91 -100 People

- OEM Services Provided:

yes

Categories: injection mold

OEM service:yes