Welding Alloy Chromium Flux Cored Wire

| Unit Price: | 1.99~2.99USD | Get Latest Price |

|---|---|

| Unit Price: | 1.99~2.99 USD |

| Min. Order: | 100 Kilogram |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Qingdao,Shenzhen |

- Product Catalog

- Company List

Product Description

- Model No.: HP 100

- standard: Aisi, Astm, Bs, Din, Gb, Jis

- place of origin: China

- species: Drawn Wire

- application: Construction, Manufacturing

- Whether alloy: Is Alloy

- Special steel: Free Cutting Steel

- tolerance: ±1%

- Processing Service: Welding

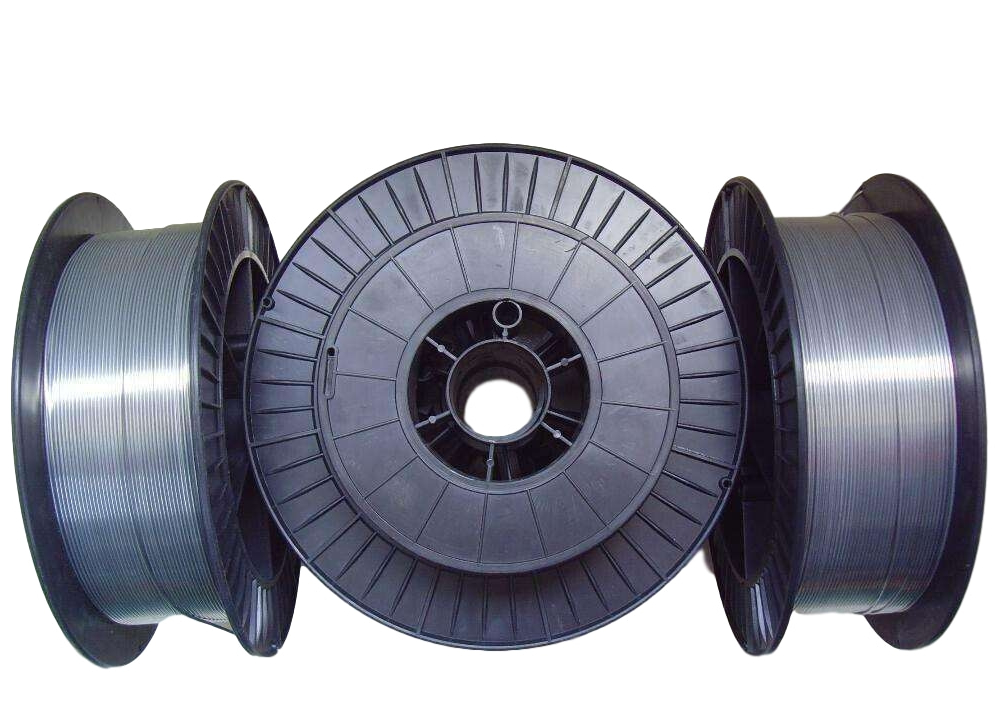

- Standard Diameter: Φ1.2, Φ1.6, Φ2.8, Φ3.2

- Package Standard 1: 15kgs/Reel

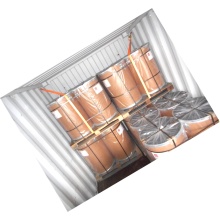

- Package Standard 2: 250kgs/Drum

- Packaging: Steel frame & steel belt fastened

- Productivity: 500 tons per year

- Brand Name: HP Plate, HP Welding

- Place of Origin: China

- Supply Ability: 10 tons per day

- Certification: ISO9001: 2015

- HS Code: 8311200000

In High Chrome Flux Cored Wire, precise alloy adjustments ensure high quality welds with excellent mechanical properties and corrosion resistance. Our mature production technology and internal quality control -exceeding the high standards of the DIN EN ISO 9001 quality system - ensure outstanding and consistent product quality to our customers and partners

Flux Cored Chromium Welding Wire delivers self-tempering deposit for Chromium Carbide hardfacing overlay.

The main features and benefits of HP Hard Surface Welding Wire include the excellent mechanical properties and corrosion resistance of all weld metal.

Besides the reliable and consistent weld quality, HP FCAW Welding Wire produces the smooth welding characteristics as the best welding material. Same as ESAB Welding Wire, HP Flux Cored Welding Wire has the minimum spatter formation.

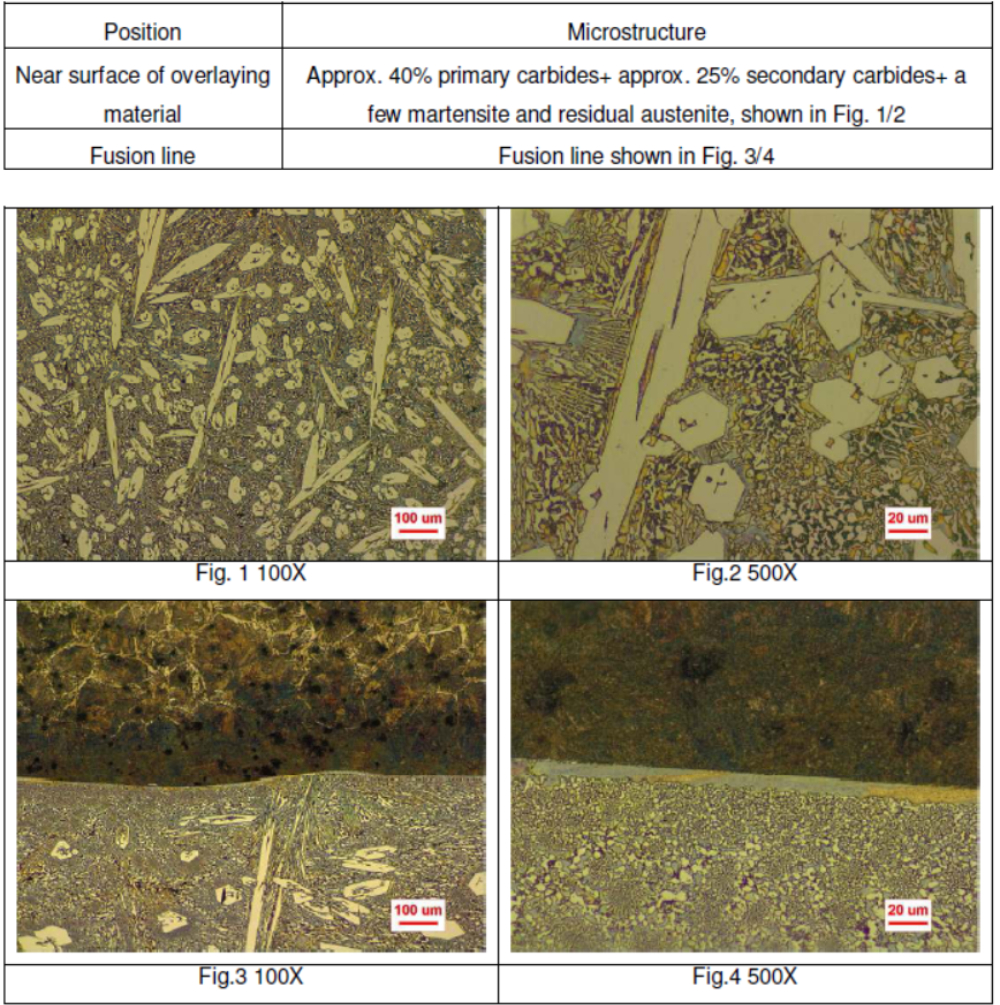

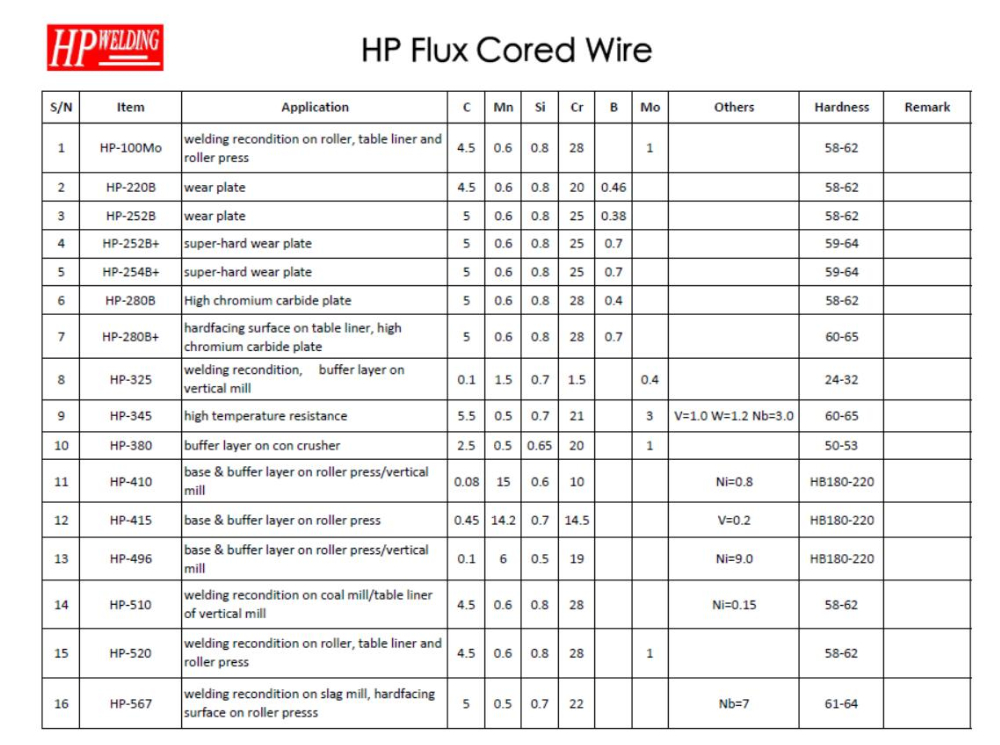

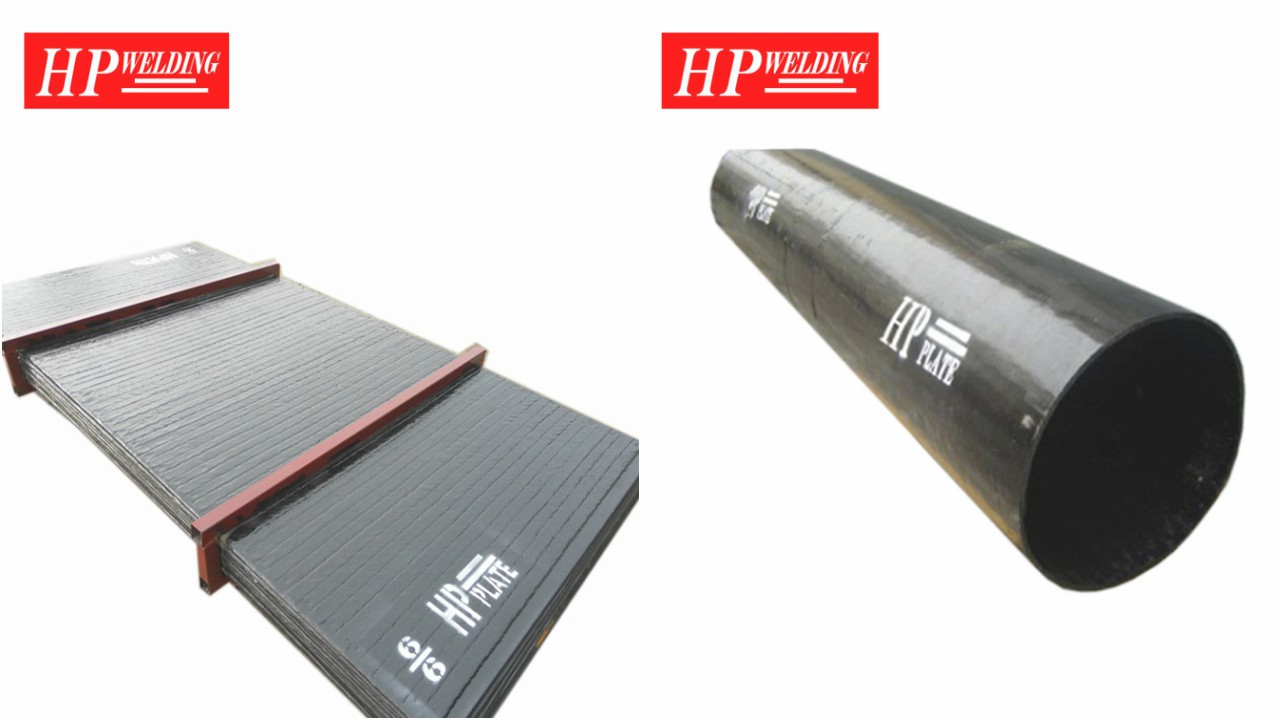

Standard Specifications of HP Wear Plate by HP welding wire:

Packing & Delivery Of Flux Cored Wires

Packing & Delivery Of Flux Cored Wires

Packing Way: Opt.1_5kg By Reel, Opt.2_ 250kg By Drum

Delivery Time: 20 days after order confirmation

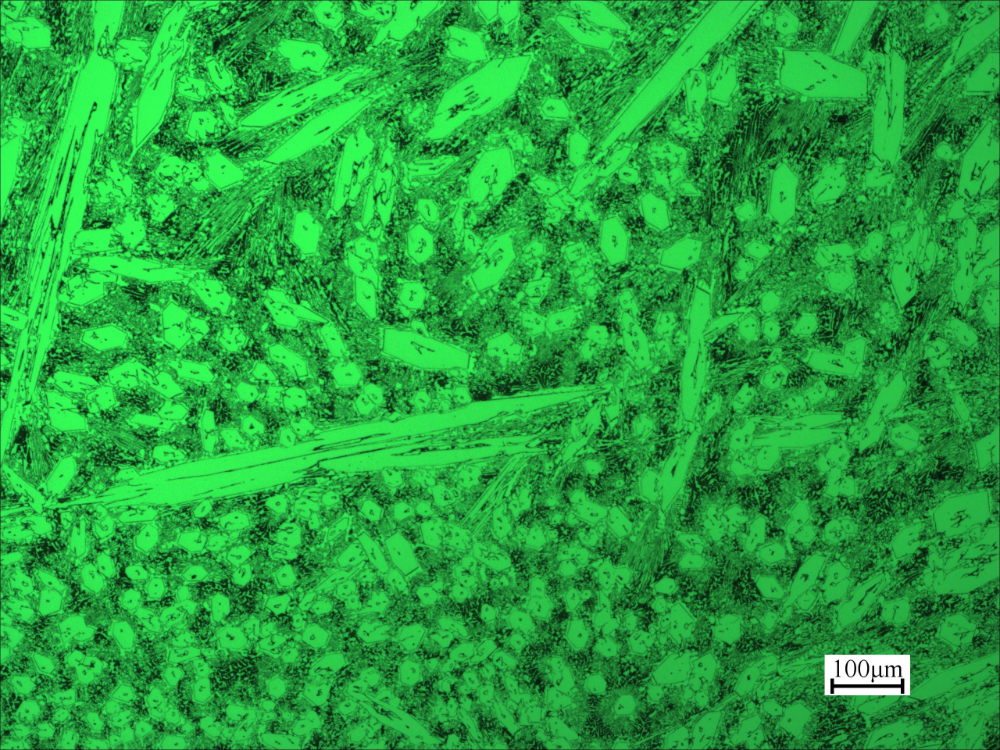

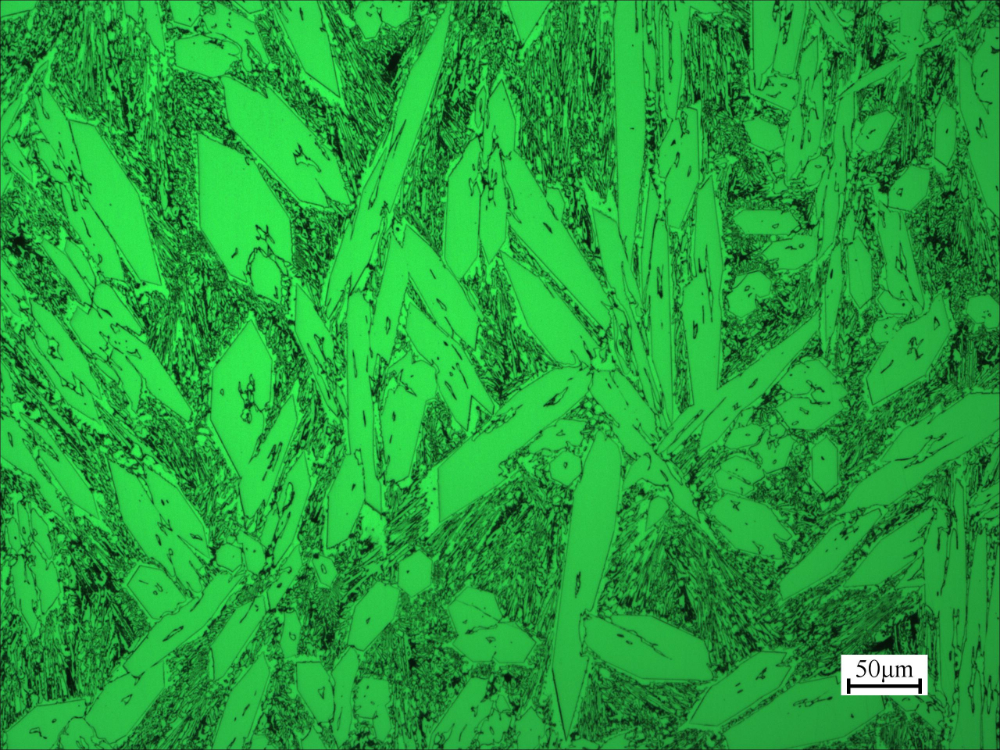

Micro Structure On Welding Deposite

Company Information

HP Wear Resistanat Group was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Group has become the most experienced expert specializing in production and sales of wear resistant products.

Test Facilities On Welding Wires

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

China

Min. Order:100

China

Min. Order:100

China

Min. Order:100

China

Min. Order:100

HUIFENG Wear Resistant Group is a professional manufacturer for wear products since 1989.

We supply wear plate, hardfacing pipe, wear parts, flux cored welding wire, wear resistant casting material & other wear solution.We have been serving cement industry, mining site, power plant, steel mill, glass industry, etc... for over 30 years through joint venture with Vautid GmbH. Our products are under ISO9001 & SGS certificated.

Basic Information

- Company Name:

HuiFeng Wear Resistant Group

- Representative:

Zhang Kunmou

- Business Type:

Manufacturer , Trade Company , Agent , Distributor/Wholesaler

- Product/Service:

Wear Plate , Flux Cored Welding Wire , Hardfacing Pipe , Wear Parts Fabrication , Clad Plate , Wear Resistant Liner

- No. of Total Employees:

51~100

- Capital (Million US $):

us$500,000

- Year Established:

2000

- Product Range:

Steel Pipes , Steel Sheets , Steel Wire

- Certificate:

Manufacturer , Trade Company , Agent , Distributor/Wholesaler

- Company Address:

No.380 SongJiaGang Rd, ZhouShi Town, Kunshan City, Jiangsu Province, China

Trade & Market

- Total Annual Sales Volume (Million US $):

US$1 Million - US$2.5 Million

- Export Percentage:

61% - 70%

- Total Annual Purchase Volume (Million US $):

Below US$1 Million

- Main Markets:

Africa , Caribbean , Oceania , Worldwide

Factory Information

- No. of Production Lines:

above 20

- No. of R&D Staff:

5 -10 People

- No. of QC Staff:

11 -20 People

- OEM Services Provided:

yes

- Factory Size (Sq.meters):

1,000-3,000 square meters

- Factory Location:

NO 168 INDUSTRIAL AVENUE, WUHU COUNTY, ANHUI PROVICE, CHINA

Other products from this company MoreEmail to this supplierCategories: High Chrome Flux Cored Wire

Business type:Manufacturer,Trade Company,Agent,Distributor/Wholesaler

Certification:ISO9001,Test ReportOEM service:yes

Our Products Range

All Products Steel Plate|--Wear Plate|--Clad Plate|--Abrasion Resistant Plate|--Chromium Carbide Overlay Plate|--Smooth Hardfacing Wear Plate|--Non Cracked Overlay Plate|--Arco Plate|--PTA W Alloy Steel Plate|--Tungsten Carbide Steel Plate|--Queench And Tempered Steel Plate|--Hardox Plate|--NM Steel Plate|--AR Steel PlateSteel Pipe And Elbow|--Hardfacing Pipe|--Wear Resistant Steel Pipe|--Coated Steel Tube|--Hardfacing Elbow|--Wear Resistant Lining Elbow|--Ceramic Lining PipeWear Resistant Liner|--Hardfacing Liners|--Hopper Liner|--Chute Liner|--Casting Liner Plate|--Truck Body Liner|--Ceramic Liner|--Rubber LinerWelding Wire|--Flux Cored Wire|--Hardfacing Cored Welding Wire|--High Chrome Flux Cored Wire|--Tungsten Carbide Flux Cored Wire|--Molybdenum Carbide Welding Wire|--Niobium Carbide Welding WireWelding ConsumablesWelding Recondition|--Welding Rebuild On Vertical Mill ComponentsCasting Materials