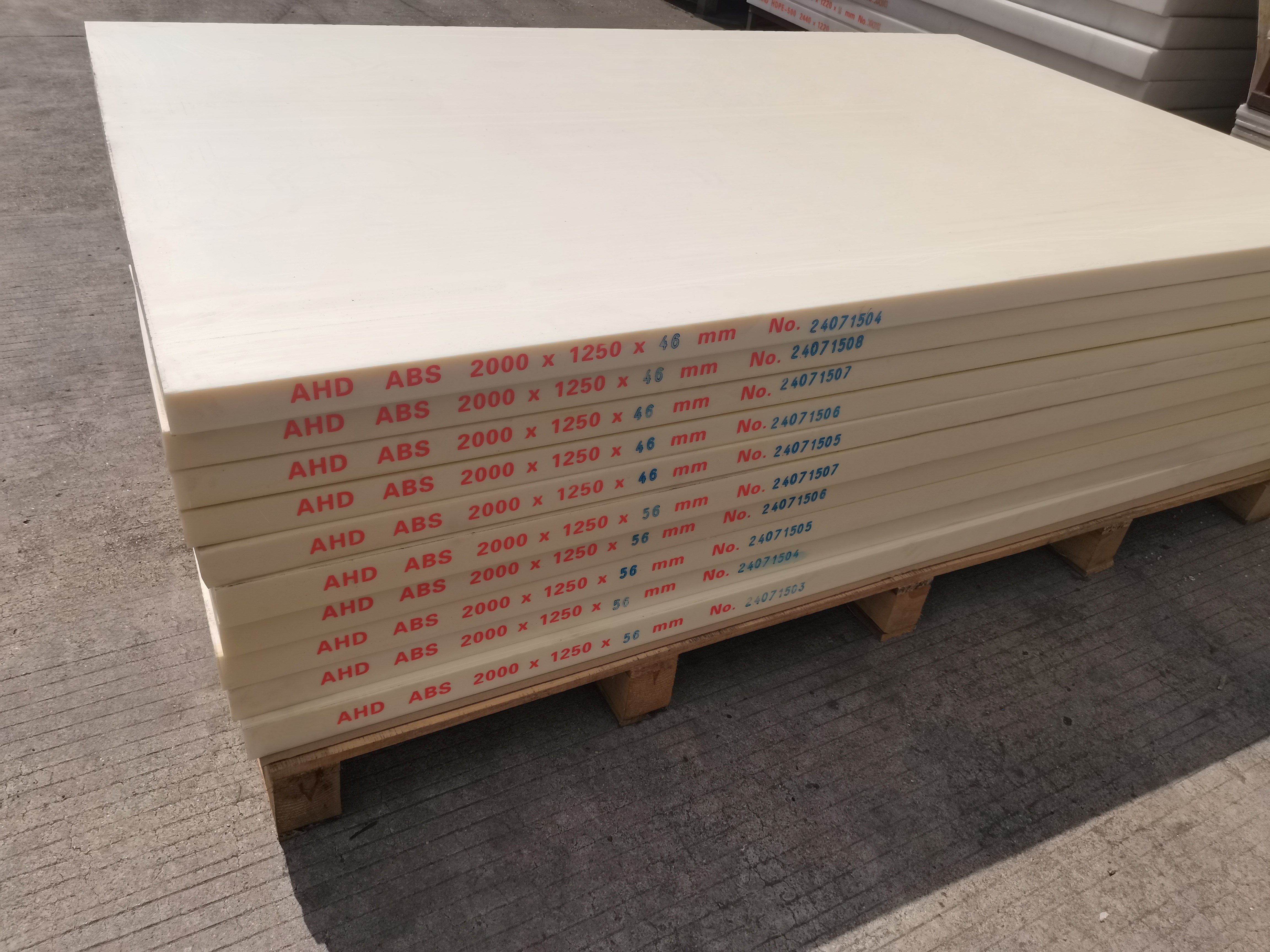

ABS Sheet is a thermoplastic plastic sheet polymerized from acrylonitrile, butadiene, and styrene. It has excellent performance and is widely used in industrial and civilian fields. It is an important material in modern manufacturing.

- High Strength and Rigidity: It has high tensile and flexural strength and is not easy to deform under force. It is used in automobiles, industrial equipment, and building structural components, etc.

- Strong Impact Toughness: It can effectively absorb and disperse impact energy and avoid brittle fractures. It is suitable for products such as sports equipment, electronic devices, and toys.

- Good Dimensional Stability: It has little dimensional change under different temperature and humidity conditions, which is very important for applications with high precision requirements such as precision instruments and electronic component brackets.

- Relatively High Heat Distortion Temperature: Generally, it can reach 80°C - 105°C and can be used normally under certain high-temperature conditions, such as in electrical appliances and automobile interior parts.

- Good Thermal Stability: It is stable within the processing temperature range, not prone to decomposition and oxidation, ensuring the processing and product quality and prolonging the service life.

- Wide Chemical Resistance: It has tolerance to common weak acids, weak alkalis, salt solutions, and some organic solvents. It can be used in non-extreme environments in industries such as chemical engineering, food processing, and pharmaceuticals.

- Adjustable Weather Resistance: By adding additives, its weather resistance in outdoor environments can be improved, enabling it to resist ultraviolet radiation, oxidation, and climate change. It is used in outdoor buildings and automobile exterior parts.

- High Gloss and Good Appearance: It can achieve a high-gloss surface treatment, with a smooth and bright appearance. It is used for the housings of household appliances and electronic products.

- Easy for Surface Treatment: Its surface can be coated, printed, and electroplated, facilitating various surface treatment processes to meet personalized and functional requirements.

- Housings and Components of Electrical Appliances: It is used for the housings of household appliances and internal circuit board brackets, etc. It has mechanical, insulating, and appearance properties and can also achieve special functions.

- Housings and Accessories of Electronic Devices: It is used to manufacture the housings and components of electronic devices such as mobile phones and computers, meeting the requirements of lightweight, personalized design, and durability.

- Interior Components: It is used for dashboards, center consoles, etc. of automobile interiors. It has good formability and texture, excellent environmental protection characteristics, improving the air quality and comfort inside the vehicle.

- Exterior Components: After weather-resistant treatment, it is used for bumpers and other exterior parts of automobiles. It has good strength and toughness, diverse shapes, and can reduce costs and weights.

- Indoor Decoration Materials: It is used to manufacture indoor decorative panels, etc. It has a variety of colors, good fire resistance, and is easy to process, meeting the design needs of different decoration styles.

- Architectural Model Making: It has stable dimensions, is easy to process, and can simulate the texture of building materials. It is used to display architectural design schemes.

It is used for the shells and structural parts of toys. It is non-toxic, odorless, brightly colored, and has good mechanical properties, meeting safety standards and children's needs.

- Housings and Accessories of Medical Devices: Some medical devices adopt it. It has good hygienic, strength, and surface properties and is convenient for disinfection and sterilization.

- Manufacturing of Sports Goods: It is used in sports goods such as snowboards. It has high strength, good toughness, and is lightweight, improving performance and safety.

It combines multiple excellent properties, meeting the strict requirements of different industries for the comprehensive performance of materials and providing more possibilities for product design and manufacturing.

It can choose from multiple processing methods such as injection molding and extrusion, which are flexible, efficient, reduce costs, achieve complex molding, and meet personalized requirements.

It is easy to process and perform surface treatment, helping designers to give play to their creativity and realize unique appearance and structural designs, enhancing brand competitiveness.

It has low raw material and processing costs, a low rejection rate, good durability, reduces the life cycle cost, and improves market competitiveness and return on investment.