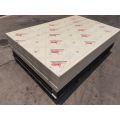

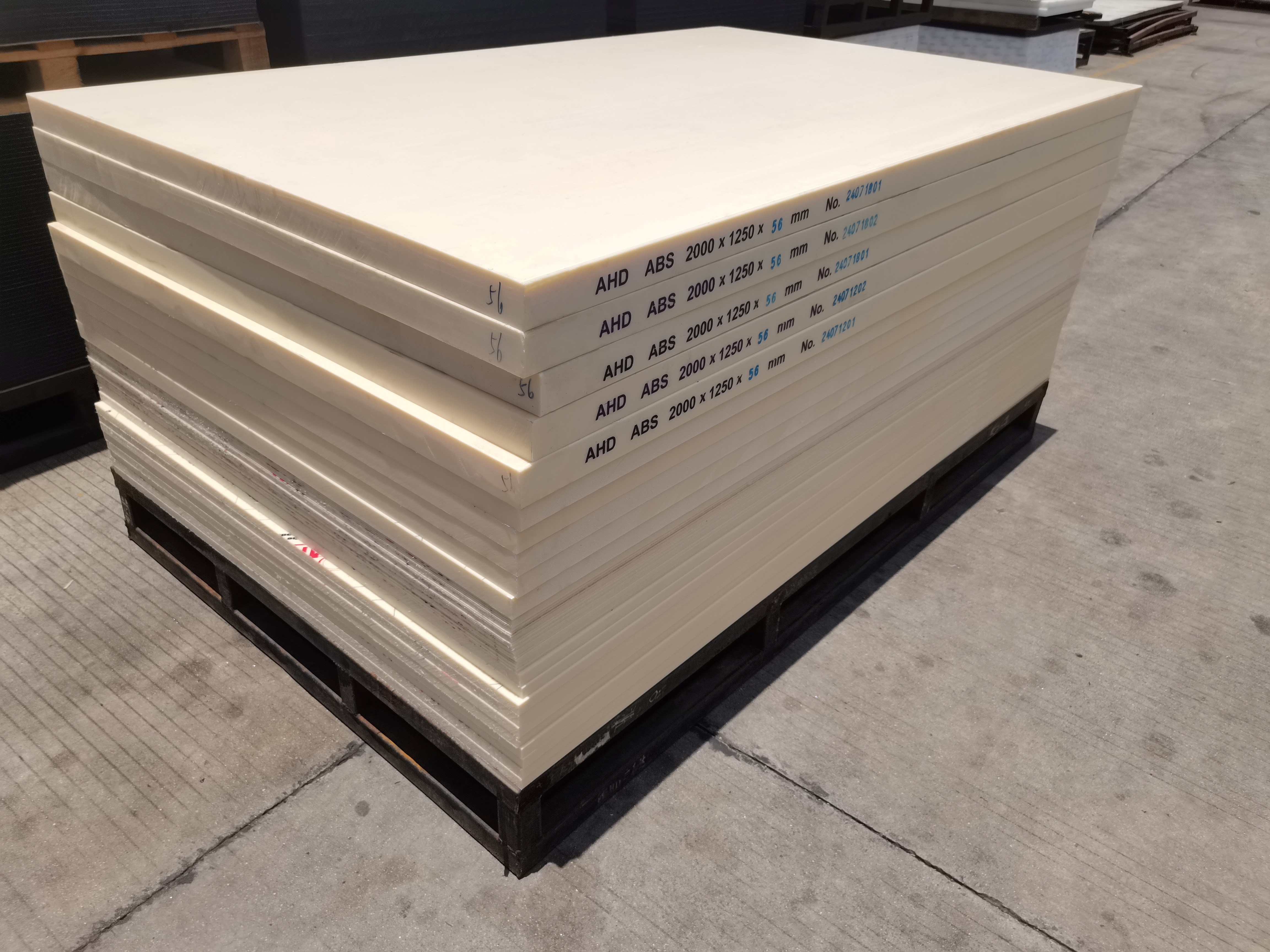

Vacuum Forming Plastic Plate Thermoplastic ABS Sheet

| Unit Price: | USD 1.95 / Kilogram |

|---|---|

| Unit Price: | 1.95 USD |

| Min. Order: | 500 Kilogram |

| Transportation: | Ocean |

| Port: | Shenzhen |

- Product Catalog

- Company List

Product Description

- Model No.: AHD241224

- place of origin: China

- Material: Abs

- Processing Service: Cutting

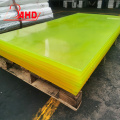

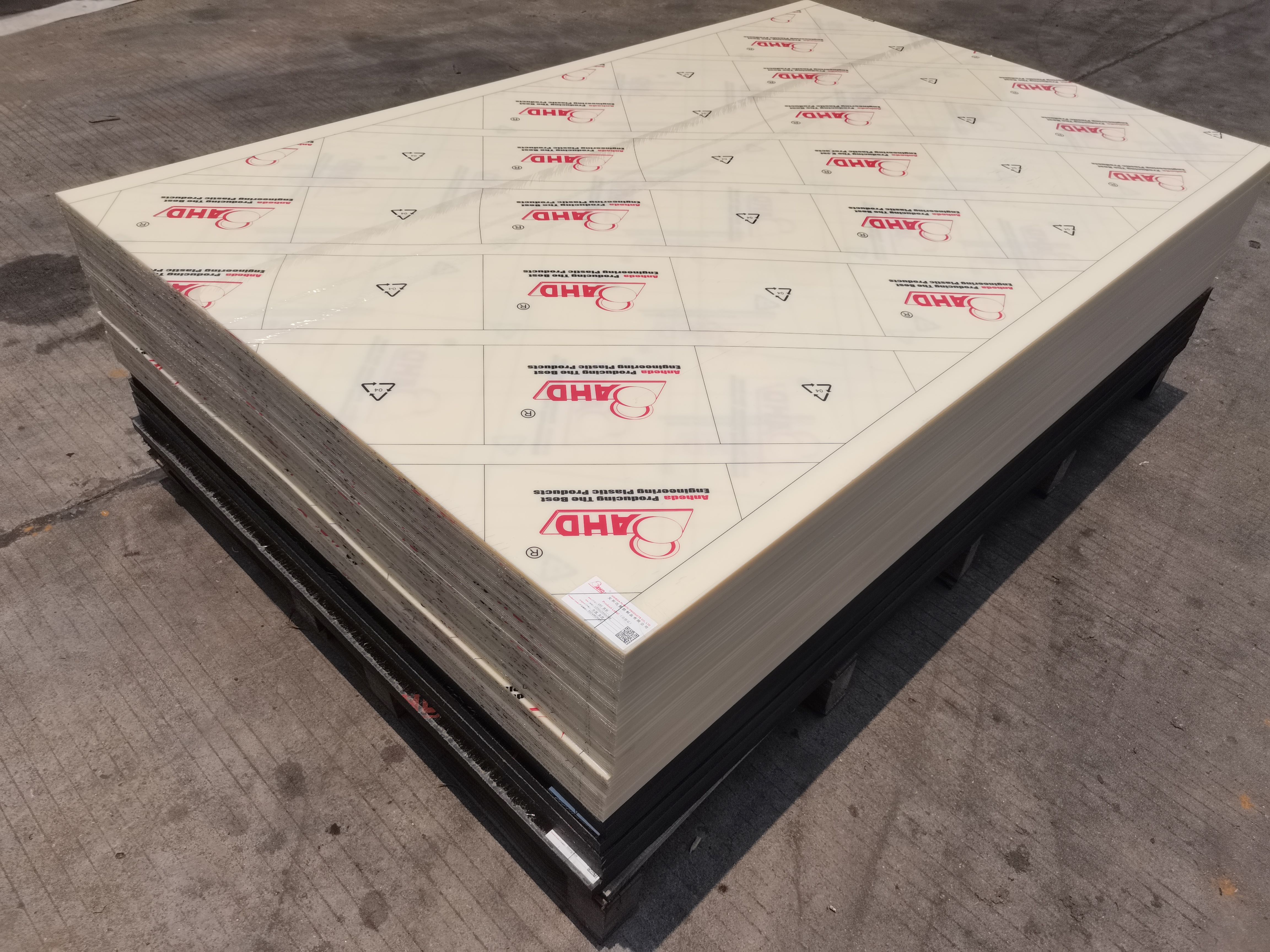

- Size: 1250*2000mm / 1500*3000mm

- Thickness: 1-150mm

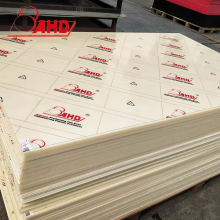

- Product Name: ABS Sheet

- Color: Beige/ Black/ White

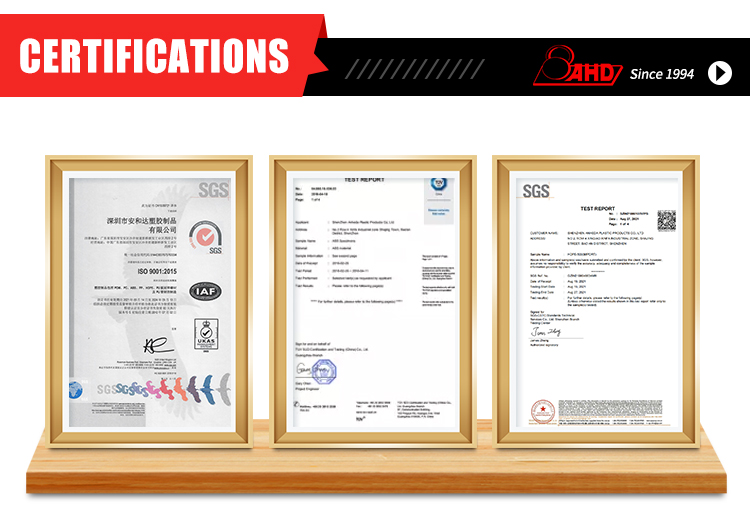

- Certificate: ISO9001:2015

- Density: 1.06g/cm3

- Brand Name: AHD

- Place of Origin: CHINA

- Certification: ISO00:2015

I. Product Overview

II. Product Characteristics

III. Product Application Areas

Guangdong China

Min. Order:100

China

Min. Order:500

Guangdong , China

Min. Order:100

China

Min. Order:500

China

Min. Order:100

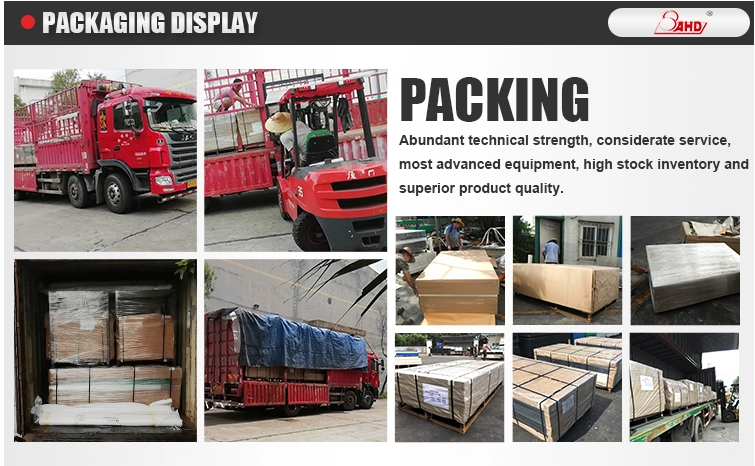

Shenzhen Anheda Plastic Products CO., Ltd, is one of the most professional and largest semi-finished engineering plastic products manufactures in China since 1994. It is also a comprehensive company that early engaged in R&D, production and distribution of semi-finished engineering plastic, our main and competitive goods, including PP, HDPE, POM, PC, ABS, PU, PA6, PEI, PPS etc sheet & rod. We Have more than 100 plastic production lines of import manufacturing equipments, and area of 20000m2;. .with over 200 employees (among them a numbers are senior engineers), with many years` of experience and customers' feedback. We are a leader in plastic industry by constant perfection of our service network, technical level and product camp. Besides AHD have obtained self-determination right of import and export and established various branches all over the country. Our goods have been exported into Malaysia, Indonesia, Thailand, Vietnam, Spain, Mexico, Colombia, Iran, Russia, Pakistan etc with positive market feedback.

AHD can satisfy customers' special requirements, we not only supply standard shapes to our customers, but also custom profiled castings for distributors or end-users and find out the best solutions for each application. All you need, all we can meet !

Basic Information

- Company Name:

Shenzhen Anheda Plastic Products Co.,Ltd

- Representative:

YUQIAN YE

- Business Type:

Manufacturer , Distributor/Wholesaler

- Product/Service:

PP sheet , PA6 sheet , ABS sheet , HDPE sheet , PU sheet , POM sheet

- No. of Total Employees:

101~200

- Capital (Million US $):

10 Million

- Year Established:

1994

- Product Range:

Plastic Rods , Plastic Sheets , Plastic Tubes

- Certificate:

Manufacturer , Distributor/Wholesaler

- Company Address:

No.2, Row 4 Xinfa Industrial zone Shajing Town, Bao'an District Shenzhen China 518125

Trade & Market

- Total Annual Sales Volume (Million US $):

Above US$100 Million

- Export Percentage:

21% - 30%

- Total Annual Purchase Volume (Million US $):

Above US$100 Million

- Main Markets:

Americas , Asia , Europe , North Europe , West Europe , Africa , Middle East , Worldwide

Factory Information

- No. of Production Lines:

250

- No. of R&D Staff:

21 -30 People

- No. of QC Staff:

21 -30 People

- OEM Services Provided:

YES

- Factory Size (Sq.meters):

30,000-50,000 square meters

- Factory Location:

No.2, Row 4 Xinfa Industrial zone Shajing Town, Bao'an District Shenzhen China 518125

Other products from this company MoreEmail to this supplierCategories: ABS Sheet

Business type:Manufacturer,Distributor/Wholesaler

Certification:ISO9001,RoHS,TUV,ULOEM service:YES

Our Products Range

All Products HDPE SheetHDPE 300 SheetPOM SheetNylon SheetPP Sheet|--PP Copolymer Sheet|--PP Homopolymer Sheet|--FR PP SHEETPU SheetPC SheetABS SheetPEI SheetHDPE RodPOM RodPA6 RodPP RodPU RodPC RodABS RodHDPE Rod and SheetPP Rod and SheetPOM Rod and SheetESD POM SheetABS Rod and SheetFR ABS SHEETPU Rod and SheetPA6 Rod and SheetPA6 SheetESD Pa6 SheetESD ABS Sheet