2014 Automatic the core filling/Co-extruder snacks food machine 86-15553158922

| Unit Price: | 25620~36520USD | Get Latest Price |

|---|---|

| Unit Price: | FOB 25620~36520 USD |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 25 Days |

| Transportation: | Ocean,Land,Air |

- Product Catalog

- Company List

Product Description

- Model No.: CY65-II

- Packaging: wooden case with plastic film

- Productivity: 50

- Brand Name: ChenYang

- Place of Origin: Jinan City ,ShanDong China

- Supply Ability: 50

- Certification: CE,ISO

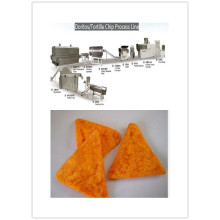

Automatic core filling snacks food machine/production line :

Main features

Core filling snack food machine take corn flour, rice flour, corn grits, millet, etc as raw materials for production. Using advanced extruding technology,through changing moulds and production technics to produce many kinds of popular snack food in the market.It has a agility scheme,strong adaptability."Low cost, high profits" is the suitable generalization of Snack food production line, especially for puff snack food.

Voltage:Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

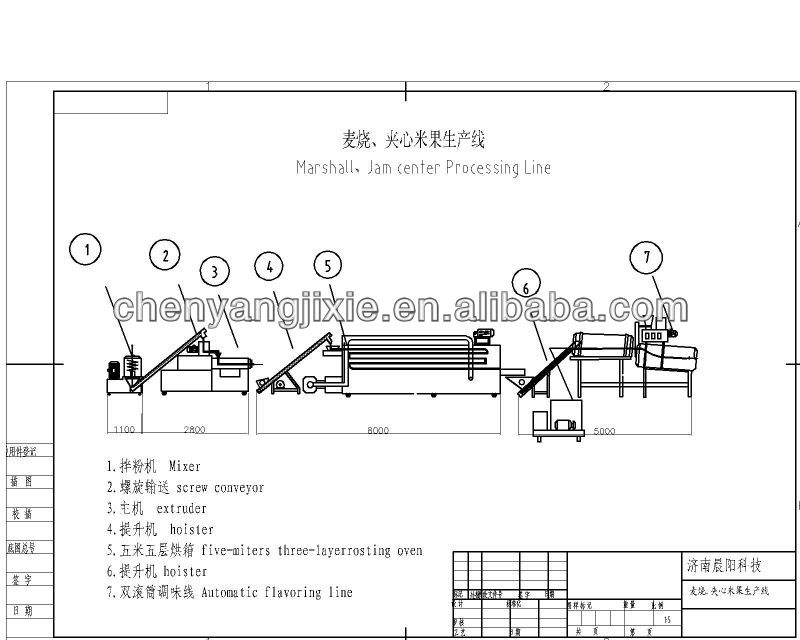

This line:Mixer---Screw conveyer---Double-screw extruder---Core filler--Multi-function shaper--Large-hoister---Three-layer electrical roasting oven--Automatic flavoring line

This line uses advanced extruding technology,through changing moulds and production technics to produce many kinds of popular snack food in the market.It has a agility scheme,strong adaptability,has gained good praise and agreement.

Technical parameter

|

Name |

Processing line |

Output |

Power |

Size |

|

Snack food |

1. mixer2.screw conveyor 3.Twin screw-extruder4.Air-conveyor 5.Roasting oven6.flavoring line |

100-120kg/h |

53kw |

15*0.8*1.6m |

|

Core filling food |

1.mixer2.screw-conveyor3.double-screw-extruder4.Multi-function shaper5.core-filler6.large-hoister7.Roasting oven8.Flavoring line |

100-120kg/h |

55kw |

18*0.8*1.6m |

The detailed information for core filling snack food processing line

|

No. |

Machine |

Motor power |

Capacity |

Dimension |

Quantity |

Function |

|

1 |

Flour mixer |

4kw |

50kg/3-5mins |

0.8*0.7*1.2m |

1 set |

To mix the raw materials such as corn flour with some additives. |

|

2. |

Screw conveyor |

1.1kw |

3.0*0.8*2m |

1 set |

To send the materials to the extruder |

|

|

3 |

CY65-II Double screw extruder |

35kw |

120-150kg/h |

2.5*1*1.8m |

1 set |

To extrude and inflate the food. |

|

4 |

Core filler |

3.5kw |

150kg/h |

0.8*0.6*1.8m |

1 set |

Filling core for the snack food inside,and have filling many taste |

|

5 |

Multi-function cutting shaper |

2 kw |

120-150kg/h |

1.1*0.8*1.3m |

1 set |

Can cut the different shapes |

|

6 |

Large-hoister |

1.1kw |

150-300kg/h |

2*0.6*2.3m |

1 set |

Transfer the snack food to roasting oven |

|

7. |

Roasting oven/dryer |

27.5kw |

100-150kg/h |

5*1.3*2m |

1 set |

To dry the food |

|

8 |

Automatic Double flavoring line |

6.5kw |

300-450kg/h 1 |

4*0.7*2m |

1 set |

Have different delicious taste |

About installation and after-sale service system:

1. We can provide factory layout according to customer`s factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the processing line arrived your country, and we will send two engineers to go and help you to install the line, teach your worker(3-4 workers) how to operate the line, until your worker know the line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc. and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the core filling food and help customer to produce good quality food according customer`s detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.

China

Min. Order:1

China

Jinan City ,ShanDong China

Min. Order:1

Jinan City ,ShanDong China

Min. Order:1

Jinan City ,ShanDong China

Min. Order:1

Jinan City ,ShanDong China

Min. Order:1

Jinan ChenYang Machinery Co.,Ltd Jinan ChenYang Machinery Co., Ltd. is located by the riverside of the Yellow River, known as the Historical Mother River, with Beijing-Shanghai, Beijing-Fuzhou, and Jinan-Qingdao Expressways passing through, easily accessible. Jinan Sunrise Co., Ltd., a standing member of Puffed Food Machinery Branch under the China Food and Packaging Machinery Industry Association, researches, develops and manufactures extrusion machinery. With the atmosphere of [Enterprising and Technology" and service concept of [Dedication to Puffed Food, Attentive Services to Customers", the company is committed to providing timely and considerate services. As a professional manufacturer of extrusion equipment,Sunrise has brought together a group of experienced experts engaged in R&D of extrusion equipment. The company products have been developed into species diversity and supporting series. It has now become the major professional manufacturer of extrusion equipment. With unremitting efforts of all staff and advanced management concept and brand, it has been improving technical standards and processing level, so as to enhance market competitiveness and overall strength. Excellent product quality and perfect after-sales service has won a good reputation for Chenyang in the industry and recognition of domestic and foreign customers. Domestic customers include: Shandong [Shenzhou", [Dingfu", [Qinyuan", Gaotang [Haojiajia", [Xiaobaobei"; Tianjin [Tianhong", [Tianlong", [Tianling"; Central China [Benbengou"; Hubei [Wolong"; Chaozhou [Jili", [Zhenxiang" Company... The products are exported to Vietnam, India, Malaysia, Indonesia, Uzbekistan Palestine, Syria, Italy, Germany, Britain, the United States, the Netherlands, Brazil and other countries and regions. Yearly-increased sales and customer recognition are our honor and pride. Welcome to cooperate with us.Basic Information

- Company Name:

Jinan Chenyang Machinery Co.,ltd

- Business Type:

Manufacturer , Trade Company

- Product/Service:

food machine , snack food extruder machine , pet food production line , corn flakes machine , artificial rice machine , protein soya food machine line

- No. of Total Employees:

N/A

- Product Range:

Electric Equipment Making Machinery , Biscuit making machine , Multi-Function Packaging Machines

- Certificate:

Manufacturer , Trade Company

- Company Address:

No 12 8 Zone,Advanced Business Center,Jinan,ShanDong ,China

Factory Information

- No. of R&D Staff:

Fewer than 5 People

- No. of QC Staff:

Fewer than 5 People

Other products from this company MoreEmail to this supplierCategories: snack food production line

Business type:Manufacturer,Trade Company