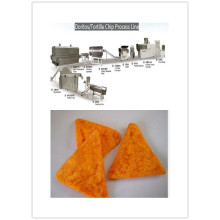

corn tortilla making machine/corn flake making machine/corn flakes machine

| Unit Price: | 85852~89850USD | Get Latest Price |

|---|---|

| Unit Price: | FOB 85852~89850 USD |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 25 Days |

| Transportation: | Ocean,Land,Air |

- Product Catalog

- Company List

Product Description

- Model No.: cy 65-II or CY70-II

- Packaging: wooden case with plastic film

- Productivity: 50

- Brand Name: ChenYang

- Place of Origin: Jinan City ,ShanDong China

- Supply Ability: 50

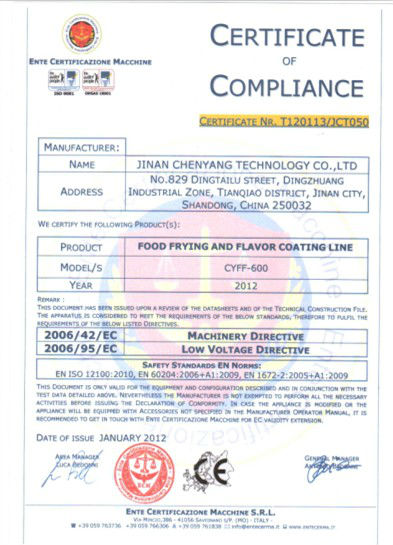

- Certification: CE,ISO

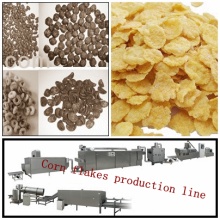

corn flakes making machine /corn flakes machine

Introduction and Features:

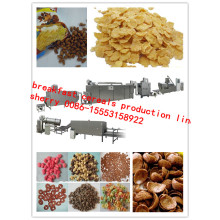

Breakfast cereals use cereals as main raw material .After extruding ,planishing ,drying ,roasting,

coating and cooling ,or after extruding and inflating to produce such as ring, grain,or flakes shape.

These kinds of food can be mixed with coffee or milk . Of course ,it can be eaten directly as snacks ,good taste.

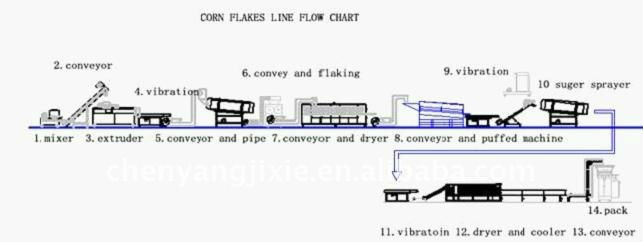

The basic production process flow:

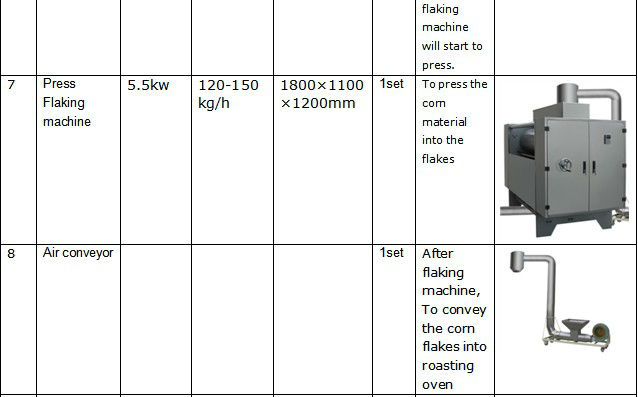

Mix the materials → extrude → shaking and shift the materials → flaking and roasting →

heated inflating → cooling secondly→ shifting sugar → roasting secondly → colling →packing

According to our process, the corn flakes made by our processing line

will have a corn fragrance and very crisp, very delicious

If without roasting secondly ,the corn flakes will be very hard , the taste will be not good and the sugar

is also difficult to penetrate into corn chips inside

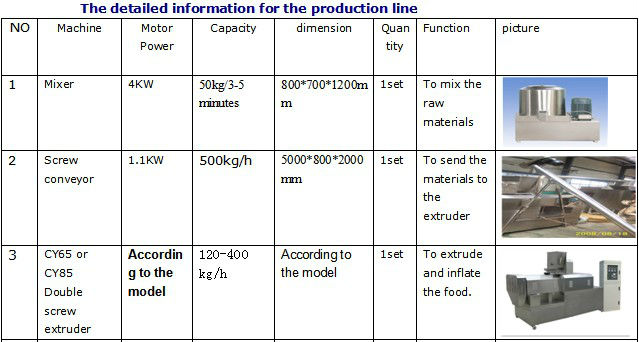

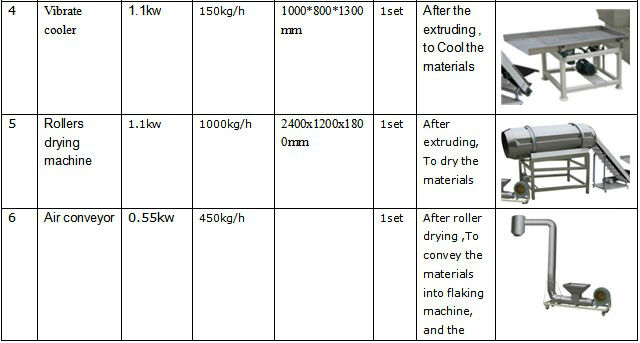

Technical parameter:

|

Model |

CY65-III Double-screw extruder line |

CY85-II Double- screw extruder line |

|

Installed capacity |

100kw |

180kw |

|

Power consumption |

70kw |

140kw |

|

output |

120-150kg/h |

300-400kg/h |

|

size |

28000x1200x2000mm |

30000x1500x2000mm |

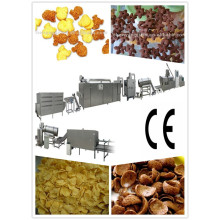

Corn flakes samples :

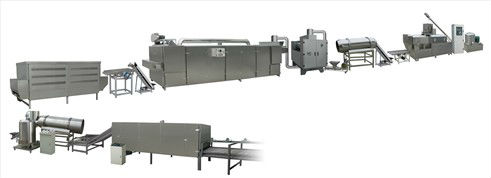

Plant pictures:

About installation and after-sale service system:

1. We can provide factory layout according to customer`s factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa,

when food processing line arrived your country, and we will send two engineers to go and

help you to install the fried snack food line, teach your worker(3-4 workers) how to operate the food line, until your worker know the food line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw,

how to change barrel etc. and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the snack food and help customer to

produce good quality food according customer`s detailed formula.

5. We provide the spare parts will at preferential price for an extended long time. 6. other item:

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments' long distance shipping;

e). Free training of equipment maintenance and operating personally;

f ). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service;

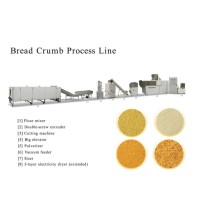

we can also make the snacks machine(3D snacks, pet food , noodle, screw, flakes, strip,

core filling snacks, nutritional rice, nutrition powder,fried snacks, and so on)

China

Min. Order:1

China

Jinan City ,ShanDong China

Min. Order:1

Jinan City ,ShanDong China

Min. Order:1

Jinan City ,ShanDong China

Min. Order:1

Jinan City ,ShanDong China

Min. Order:1

Jinan ChenYang Machinery Co.,Ltd Jinan ChenYang Machinery Co., Ltd. is located by the riverside of the Yellow River, known as the Historical Mother River, with Beijing-Shanghai, Beijing-Fuzhou, and Jinan-Qingdao Expressways passing through, easily accessible. Jinan Sunrise Co., Ltd., a standing member of Puffed Food Machinery Branch under the China Food and Packaging Machinery Industry Association, researches, develops and manufactures extrusion machinery. With the atmosphere of [Enterprising and Technology" and service concept of [Dedication to Puffed Food, Attentive Services to Customers", the company is committed to providing timely and considerate services. As a professional manufacturer of extrusion equipment,Sunrise has brought together a group of experienced experts engaged in R&D of extrusion equipment. The company products have been developed into species diversity and supporting series. It has now become the major professional manufacturer of extrusion equipment. With unremitting efforts of all staff and advanced management concept and brand, it has been improving technical standards and processing level, so as to enhance market competitiveness and overall strength. Excellent product quality and perfect after-sales service has won a good reputation for Chenyang in the industry and recognition of domestic and foreign customers. Domestic customers include: Shandong [Shenzhou", [Dingfu", [Qinyuan", Gaotang [Haojiajia", [Xiaobaobei"; Tianjin [Tianhong", [Tianlong", [Tianling"; Central China [Benbengou"; Hubei [Wolong"; Chaozhou [Jili", [Zhenxiang" Company... The products are exported to Vietnam, India, Malaysia, Indonesia, Uzbekistan Palestine, Syria, Italy, Germany, Britain, the United States, the Netherlands, Brazil and other countries and regions. Yearly-increased sales and customer recognition are our honor and pride. Welcome to cooperate with us.Basic Information

- Company Name:

Jinan Chenyang Machinery Co.,ltd

- Business Type:

Manufacturer , Trade Company

- Product/Service:

food machine , snack food extruder machine , pet food production line , corn flakes machine , artificial rice machine , protein soya food machine line

- No. of Total Employees:

N/A

- Product Range:

Electric Equipment Making Machinery , Biscuit making machine , Multi-Function Packaging Machines

- Certificate:

Manufacturer , Trade Company

- Company Address:

No 12 8 Zone,Advanced Business Center,Jinan,ShanDong ,China

Factory Information

- No. of R&D Staff:

Fewer than 5 People

- No. of QC Staff:

Fewer than 5 People

Other products from this company MoreEmail to this supplierCategories: snack food production line

Business type:Manufacturer,Trade Company