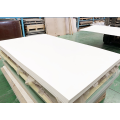

High-Insulation White SMC Sheet For The Electric Power Industry

| Unit Price: | USD 2.35 - 3.55 / Kilogram |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

- Product Catalog

- Company List

Product Description

- Model No.: SMC Sheet-001

- place of origin: China

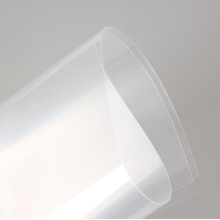

- species: Insulation Sheet

- Material: Fiberglass

- Scope of application: High Temperature

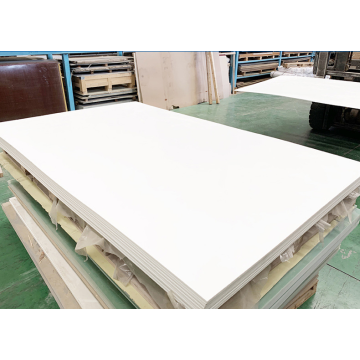

- Size: 1010×2020—1250×2500mm

- Color: White/Red

- Thickness: 2-60mm

- Product Name: SMC Insulation Sheet

- Features: High temperature resistance

- Density: 1.85kg/m3

- Certificate: SGS

- Flame Retardant: V0-V1-Non-flame retardant

- Process: Mirror High Gloss

- Voltage Resistance: 1mm=10kV

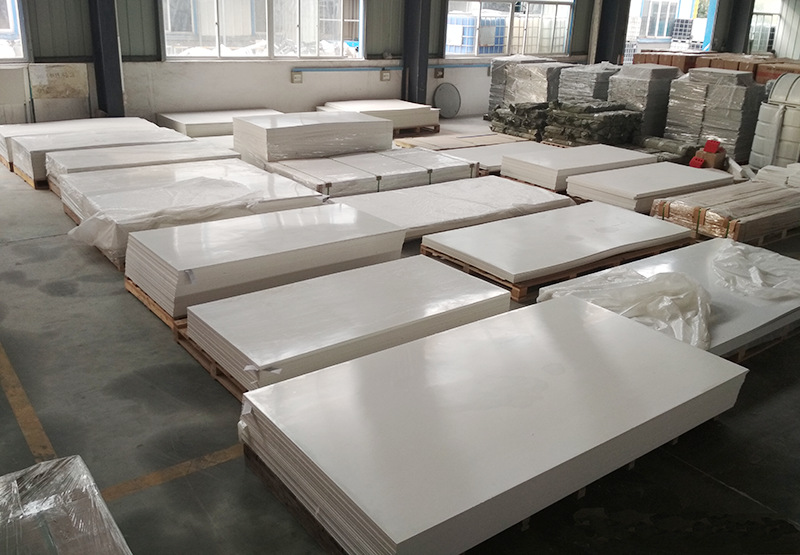

- Packaging: Pallet

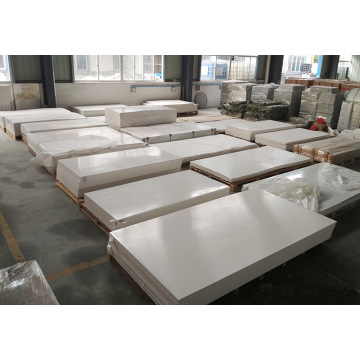

- Productivity: 20 Tons/month

- Place of Origin: China

- Supply Ability: 20tons/month

- Certification: SGS

- HS Code: 3921909090

The composition of the SMC insulation sheet includes the following components:

Glass Fiber: The SMC insulation sheet is reinforced with glass fibers, which provide high strength and rigidity to the material. The glass fibers enhance the mechanical properties of the sheet, making it capable of withstanding mechanical loads and impacts.

Plastic Matrix: The plastic matrix in the SMC insulation sheet is typically made of thermosetting resin, such as polyester or epoxy. The plastic matrix provides the structure and shape of the sheet, as well as contributes to its mechanical and thermal properties.

Fillers: Various fillers, such as mineral fillers or flame retardant fillers, are added to the SMC insulation sheet to enhance its performance. Fillers improve the dimensional stability, flame resistance, and other specific properties of the sheet.

Advantages And Features Of SMC Sheet

SMC insulation board has excellent corrosion resistance and high-temperature resistance, which can effectively prevent short circuits and leakage of power equipment, no warping, no deformation, no static electricity, and has high strength and rigidity, and can withstand certain mechanical loads.

It is not easy to undergo physical and chemical reactions, and it is moisture-proof, mildew-proof, and antibacterial to increase its service life.

1. High mechanical strength: SMC insulation board has high mechanical strength, which enables it to withstand large loads and stresses.

2. Flame retardancy: SMC material has good flame retardancy, usually reaching FV0 level, suitable for strict safety standards.

3. High dielectric strength: SMC insulation board can withstand high voltage without breakdown, and is suitable for power systems and electronics industries.

4. Low water absorption: Low water absorption ensures the stability of the material in a humid environment, reducing changes and performance degradation caused by water absorption.

5. Dimensional stability: The SMC insulation board has a small warping degree, which ensures accuracy and reliability during processing and use.

6. Development trend: With the continuous advancement of technology and the growth of market demand, the production process and performance of SMC insulation boards are also constantly improving. In the future, more functional materials may appear to meet the needs of specific applications.

Application Of SMC Sheet

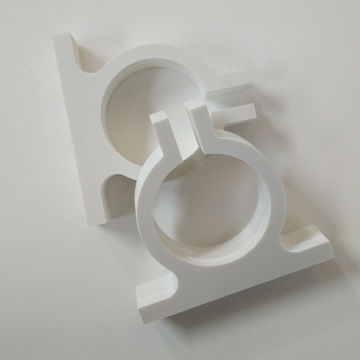

SMC insulation board is widely used in automobiles, transportation rail, aerospace, power, electronics, communication, construction, insulation parts, and other fields.

Common application range

1. Power field: transformer, switch cabinet, bus cable bracket, electrical isolation board, etc.

2. Railway field: railway power high-voltage load switch, signal equipment, temporary station building, etc.

3. Electronic field: electronic equipment chassis, communication cabinet, instrument bracket, electronic circuit board, etc.

5. Construction field: floor, partition wall, bathroom cubicle, kitchen counter, etc.

Guangdong China

Min. Order:100

Guangdong China

Min. Order:100

Guangdong China

Min. Order:100

Guangdong China

Min. Order:100

Guangdong China

Min. Order:100

Shenzhen Xiongyihua Plastic Insulation Limited was established in 2006 in Shenzhen, is a manufacturer and trader, specialized in the research, development and production of Engineering Plastic and Insulation Plastic, such as phenolic laminated, epoxy fiberglass, durostone, nylon PA6, POM, PE, PVC. PU, PTFE and ABS.

We also have processing equipment, like CNC carving machine and laser engraving machine to engraving, cutting, bending and drilling. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction. As a result of our products and outstanding customer service, we have gained a global sales network reaching India, Vietnam, Thailand, Indonesia, Philippines, Malaysia, Turkey, Pakistan, Dubai, and some other countries from European, like Britain, France and German. And America, Australia, etc.For the past 15 years, XiongYiHua has built its reputation by producing quality products to serve in the after market, distribution. The company also recognizes the importance of establishing close partnerships with its customers.

One of Top 10 Plastic Insulation manufactures in China Mainland, specializing in plastic extrusion, casting, injection molding etc.

54 production lines for Rod.

17 production lines for sheet.

CNC: 5 sets, lathe: 5 sets, Driller: 3 sets, Grinder: 2 sets, Cutting machine:2 sets.

Established long term relationship from Europe, USA, South America, South Asia etc., and enjoying great reputation in plastic industry.

Basic Information

- Company Name:

SHENZHEN XIONGYIHUA PLASTIC INSULATION LTD

- Representative:

CaiKun Wu

- Business Type:

Manufacturer , Distributor/Wholesaler

- Product/Service:

POM SHEET , FR4 Sheet , Nylon Sheet , Bakelite Sheet , ABS Sheet , PTFE Sheet

- No. of Total Employees:

51~100

- Capital (Million US $):

10000000RMB

- Year Established:

2006

- Product Range:

Insulation Materials & Elements , Plastic Rods , Plastic Sheets

- Certificate:

Manufacturer , Distributor/Wholesaler

- Company Address:

NO.2 Longxian Road,Xinsheng Community,Longgang Street,Longgang District, Shenzhen,Guangdong,China

Trade & Market

- Total Annual Sales Volume (Million US $):

US$10 Million - US$50 Million

- Export Percentage:

71% - 80%

- Total Annual Purchase Volume (Million US $):

US$1 Million - US$2.5 Million

- Main Markets:

Americas , Asia , Europe , North Europe , West Europe , Africa , East Europe , Middle East , Oceania , Worldwide , Other Markets

Factory Information

- No. of Production Lines:

10

- No. of R&D Staff:

5 -10 People

- No. of QC Staff:

5 -10 People

- OEM Services Provided:

yes

- Factory Size (Sq.meters):

5,000-10,000 square meters

- Factory Location:

NO.2 Longxian Road,Xinsheng Community,Longgang Street,Longgang District, Shenzhen,Guangdong,China

Other products from this company MoreEmail to this supplierCategories: CNC Processing Product

Business type:Manufacturer,Distributor/Wholesaler

Certification:CE,FDA,ISO14001,ISO9001,REACH,RoHS,FCC,MSDS,Test Report,TUVOEM service:yes

Our Products Range

All Products P O M|--POM Sheet|--POM RODNYLON|--PA6 Sheet|--PA6 ROD|--MC Nylon Sheet|--MC Nylon RODPTFE Products|--PTFE Sheet|--PTFE ROD|--PTFE Cloth3240/FR4/G10 Epoxy Fiberglass Sheet|--3240 Epoxy Glass Sheet|--FR4 SheetPhenolic Laminated Bakelite Sheet|--Bakelite Sheet|--3025 Phenolic Cotton Laminated Sheet|--3021 Phenolic Paper Laminated Sheet|--3025 Phenolic Cotton Laminated RodABS/HIPS/PS|--ABS Sheet|--ABS Rod|--HIPS SheetPVC Products|--PVC Sheet|--PVC ROD|--PVC Film|--PVC Foam SheetAcrylic ProductsEngineering PlasticCNC Processing ProductPU Polyurethane|--PU Sheet|--PU RODPE Sheet|--PE SheetMica SheetPP Sheet