High temperature curing oven sale

| Unit Price: | USD 388 - 398 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CIF,EXW,FCA |

| Min. Order: | 1 Bag/Bags |

| Delivery Time: | 7 Days |

| Transportation: | Ocean,Land |

| Port: | Shenzhen |

- Product Catalog

- Company List

Product Description

- Model No.: HYJ-D-0002

- species: Drying Oven

- application: Medicine Processing, Chemicals Processing, Plastics Processing

- Old and new: New

- place of origin: China

- Core selling point: Competitive Price

- warranty period: 2 Years

- Out-of-warranty service: Field Maintenance And Repair Service, Video Technical Support, Online Support, Spare Parts

- Applicable industry: Manufacturing Plant, Machinery Repair Shops, Printing Shops, Advertising Company

- Where to provide local services (in which countries are there overseas service outlets): Viet Nam, Pakistan, India, Mexico

- Marketing type: Ordinary Product

- Mechanical test report: Provided

- Video factory inspection: Provided

- Core component warranty period: 2 Years

- Core components: Motor

- Heat source: Electric Heating

- material: Other

- Voltage: 110v/220v/380v/415v

- Size: Customized

- Name: Industry Oven

- Blower: 370w

- Packaging: wood cases

- Productivity: 600

- Brand Name: HENGYIJIA

- Place of Origin: China

- Supply Ability: 50

- Certification: CE ISO

Product description

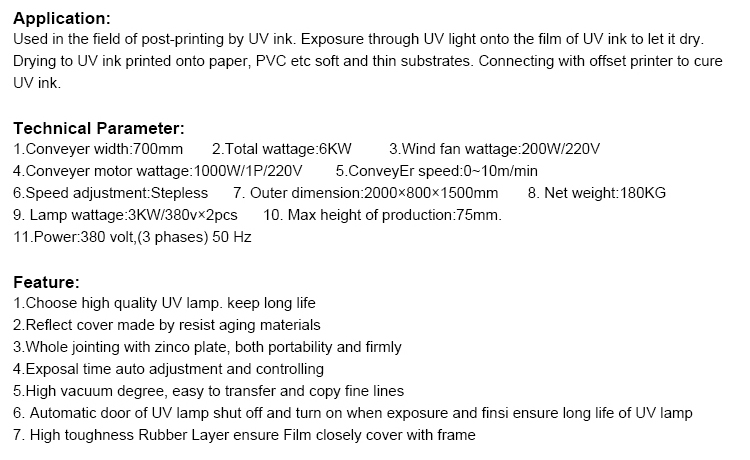

Application area:

Die-casting, printing, printing, printing, printing, dehumidification, etc., foods, bottles, bottles, bottles, etc. , Die-casting work , Nishi-Sho bottle , Ampoule bottle , Dehumidifier bottle , Dehumidifier glass bottle , Wanaka 药 and other foods Workplace arrangement, high production efficiency, domestic system in front of me, middle-aged pharmaceuticals, drinks, daily chemicals indispensable equipment Noichi.

Type: Heated circulation, etc. Unmatched box Yes Unusual crafts, in fact unequal suitable ovens. For example, high-temperature screen printing, dyeing, printing, printing, etc. Industrial drying, dehumidifying, etc., foods that can be reduced, textiles, small cases, etc. Industrial drying, baking, etc.

Merit features:

1. A3 cold rolling sheet production for outer rolling, surface rolling lacquer processing, high-density silicon,

2. Filling with acid aluminum, heat insulation of the stove box

3. Convection in the convection system, heat storage, temperature homogenization, power saving, high efficiency, convenience of use, automatic constant temperature, regular time.

Safety performance: Intelligent PID automatic constant temperature control, timekeeping, timekeeping automatic warning and disconnection heating body, super temperature automatic warning and disconnection heating body, power source thermostat, etc.

Safety box construction principle: Electric heating flat plate wire heating tube for external heating, external heating, general electric energy saving, high energy saving, high pressure, high pressure, internal box, forming hot water circulation, box body construction, convection stirring Special points such as technology, emergency temperature control, automatic temperature control, speed control, failure report, etc., safety of use, convenience, energy saving, energy saving, etc.

High-temperature fiber box technology requirements: Excellent fiber plate for in-firer, excellent molded color sheet for outer wall, post-molded sheet for girder, heat-retaining asbestos, heat-retaining electric heating tube, high-temperature non-fiber Low-pitched voice for asbestos, high-pressure, high-pressure, high-pressure, heat-retaining, asbestos, fiber, and asbestos.

Operation explanation

First step: Contact 380V power source, open power source supply desk (must be opened at the same time).

Second step: Exploding heating, and then setting demand temperature sum super temperature insulation (super temperature insulation setting temperature ratio required temperature high 30 degrees).

Third step: After the temperature is reached, the opening time of the product and the setting product.

Fourth step: After the arrival of the roasting time, the heating and the roasting were stopped after the meeting was reported.

Note:

Use of industrial paint box Environmental environment ban 靠 Near easy burning Explosive goods Nyotenna water, oil lacquer. No, it's an explosive danger. At the same time, when the industrial oven box is in use, the tail gas exhaust port and the circumscribed exhaust pipe are essential.

Ota class, oil lacquer paint, high temperature environment, part of the human body, injuries, gas production, expulsion from time to time, health of the injured person.

China

Min. Order:1

China

Min. Order:1

China

Min. Order:1

China

Min. Order:1

China

Min. Order:1

Our History

Shenzhen Heng Yi Jia Technology Co., Ltd. has focused on paint spraying equipment for over20 years in China. We started as a small operation, but now have become one of the leading painting line suppliers in the coating industry in China.

Today,Shenzhen Heng Yi Jia Technology Co., Ltd. has been one of the top producers of quality automatic spraying line and new technologies, such as: automatic paint spraying line, UV paint spraying line(uv lines), spray chrome line, mini auto painting line, spray chrome equipment and accessories of coating equipment of vacuum metallizing machine(metallizer), Automatic UV plating vacuum line, spray booth, coating chain, UV curing oven, automatic spray chrome equipment&line, spray powder coating line & equipment and so on.

Our factory

Shenzhen Heng Yi Jia Technology Co., Ltd. is located in the China The beautiful coastal city-Shenzhen. As a global supplier in auo paint spraying line, UV paint spraying line, mini auto painting line, spray chrome line, spray chrome equipment and accessories of coating equipment. Heng Yi Coating Technology is to create added value for customers around the world.

Our product

Our products includes the following:

1, Automatic paint spraying line

2, UV paint spraying line

3, Mini automatic paint spraying machine

4,small automatic spray coating machine

5.UV spray coating line

6. automatic spray painting line

7.Industrial tunnel oven

8.Fixed oven

9.UV curing machine

We supply coating products all over the globe to a wide range of companies worldwide, ranging from large multinational organizations to small individual companies.

Product Application:

Spray painting plant for Industry use are widely used in the following industry, such aspackage coating plant:

--- Glass packages coating for cosmetics, perfume, wine, caps, bottles and other parts

---Painting plant for product paint surface finishing

---Vacuum coating plant

Spray chrome equipment with formula which from our second production line, are widely used for cmetallzing oating, and vacuum coating machine etc.

Our certificate:

We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, ISO14000:14001 quality control system, CE certificate, etc.

Production equipment

We are capable of mixing and producing an paint spraying line, UV lines and offer some of the most advanced manufacturing capabilities available, including vacuum coating machine, mini paint spray machine and spray chrome machine etc.

Production market:

We have customers from both domestic market and oversea market.Heng Yi Jia Technology Sales managers can speak fluent English for good communication. Our main sales market:

China : 50%

USA: 10%

Spain:5%

Thailand:3%

Singapore:2%

India: 20%

Our service for coating equipment.

Besides our existing molded spray painting line, auto paint spray line, uv paint line, mini paint spray line, spray chrome machine, also can produce other coating line according to the drawings from our customers. We control the product quality critically for every step during the manufacturing from custom coating equipment. We offer technical support that is second to none. installation at local.

Basic Information

- Company Name:

Shenzhen Heng Yi Jia Technology Co., Ltd.

- Representative:

Wu Juhua

- Business Type:

Manufacturer

- Product/Service:

Powder coating machine , Automatic Spray painting coating Line , UV Coating machine Line , small automatic spray coating machine , tunnel oven , semi-automatic spray coating line

- No. of Total Employees:

51~100

- Capital (Million US $):

50万

- Year Established:

2016

- Product Range:

Other Industrial Filtration Equipment , Laser Cutting Machines , Pumps & Parts

- Certificate:

Manufacturer

- Company Address:

No.2 Street 5 Lao Keng Industrial Zone Keng Zi Shenzhen China

Trade & Market

- Total Annual Sales Volume (Million US $):

Below US$1 Million

- Export Percentage:

81% - 90%

- Total Annual Purchase Volume (Million US $):

Below US$1 Million

- Main Markets:

Americas , Asia , Europe , North Europe , West Europe , Africa , Caribbean , East Europe , Middle East , Oceania , Worldwide , Other Markets

Factory Information

- No. of Production Lines:

5

- No. of R&D Staff:

5 -10 People

- No. of QC Staff:

11 -20 People

- OEM Services Provided:

yes

- Factory Size (Sq.meters):

3,000-5,000 square meters

- Factory Location:

No.2 Street 5 Lao Keng Industrial Zone Keng Zi Shenzhen China

Other products from this company MoreEmail to this supplierCategories: Fixed curing oven

Business type:Manufacturer

Certification:ISO9001,ISO14001,GB,CE,MSDS,UL,TUVOEM service:yes

Our Products Range

All Products Mini coating machineUV coating linePainting line sprayGlass coating machinePlastic coating machineWood coating machinePowder coating linePowder coating machineOnline reciprocating machinespray chrome machine|--spray chrome processing|--spray chrome machine|--spray chrome gun|--spray chrome chemicalsCuring oven|--Tunnel oven|--Fixed curing ovenUV curing machinePaint booth accessories|--High Effeciency filter|--Electrostatic spray gun|--spray gunspray painting serive|--UV coating|--water coating|--metal coating serice|--glass bottle painting serice|--plating metallizing|--uv painting processingUngrouped|--Handles & KnobsFully Automatic Spray Painting Line|--Plastic Product Painting Line|--Metal Product Painting Line|--Glass Product Painting Line|--Ceramic Product Painting Line|--Woodware Painting LineAuto UV Spray Coating LineSmall Auto Spray Painting Line|--Mini Circuit Auto Type|--Mini Front Auto Type|--Flat Movable Auto Type|--Rotation Head-acting Type|--Circling Double-acting Type|--Painting Machine for Pipe ProductsReciprocator Painting Line|--Spot & Movable Type|--On-Line Type Paint Sprayer|--Reciprocating Machine TypeRobotic Painting LineVacuum Coating Machine|--Vacuum Evaporation Metallizer|--Vacuum Ion Coater|--Magnetic Control Sputter Coaters|--Optical Vacuum Coating MachineSpray Chrome Technologies|--Fully Automatic Spray Chrome Line|--Spray Chrome Machine|--Spray Chrome ChemicalsPowder Coating|--Powder Coating Line|--Spray Powder Booth|--Manual Powder Coating MachineClean Room|--10000 Classes Clean RoomOven|--Heat Curing Oven|--UV Curing Oven|--Tunnel OvenCoating Line Accessories|--Air Supply System|--Exhaust Gas Exhaust System|--Industrial Air Shower|--Clean Air Filter|--Automatic Spraying Line Fixture|--Automatic Spray Painting GunProduct Processing|--UV Vacuum Metallizing Coating Service|--Spray Chrome Metallizing Service|--Spray Painting Services