Industrial Walk In Oven Dryer Equipment

| Unit Price: | Get Latest Price |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 10 Days |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

- Product Catalog

- Company List

Product Description

- Model No.: HYJ-B-0350

- species: Drying Oven

- Old and new: New

- place of origin: China

- Core selling point: High Safety Level

- warranty period: 1 Year

- Out-of-warranty service: Online Support

- Mechanical test report: Provided

- Video factory inspection: Provided

- Evaporation capacity (kg/h): 10000

- Heat source: Gas Heating

- Packaging: Wood cases

- Productivity: 500

- Brand Name: HENGYIJIA

- Place of Origin: China

- Supply Ability: 50

- Certification: CE ISO

Industrial Walk In Oven Dryer Equipment

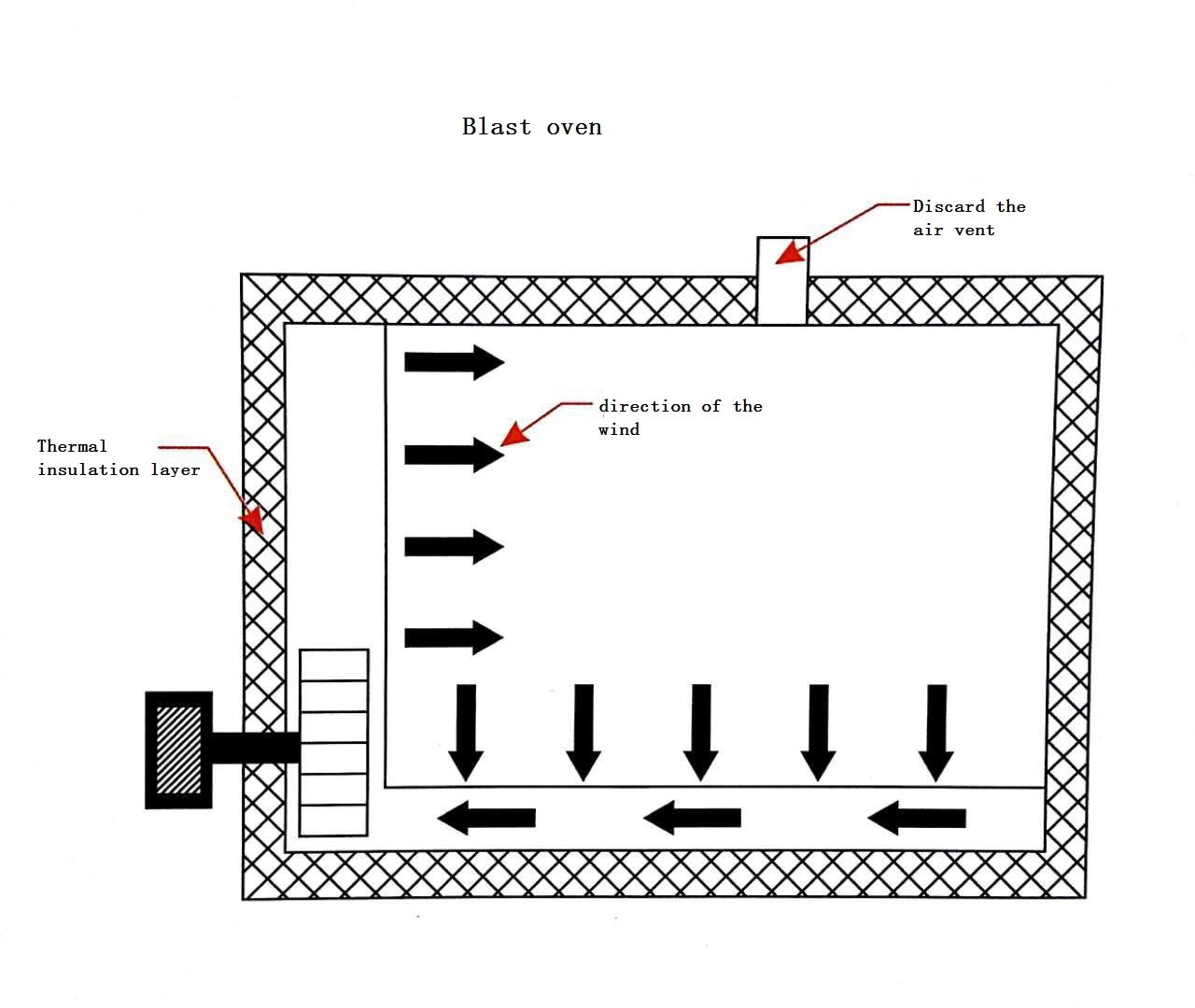

Industrial fixed curing oven is specifically designed for customers that have limited floor space. Even though the footprint of this composite curing ovens may be small, it still offers exceptional uniformity and high performance. The full horizontal airflow and standard top return air duct helps to deliver a high rate of airflow. And, with high energy transfer rates, this drying oven industrial design helps to keep costs down and save time. The TR Series walk in oven model is ideal for most thermal processes that require up to 800f maximum temperature.Use this walk in oven for many different types of applications including pre-heating, annealing, powder coating, curing, drying, dehydrating, heat shrinking and heat setting, testing, and more!

| Temperature table | one | Wind wheel | one |

| Thermocouple | one | Contactor | one |

| Time system | one | Leakage switch | one |

| Wind motor | one | Over temperature meter | one |

Detailed Images

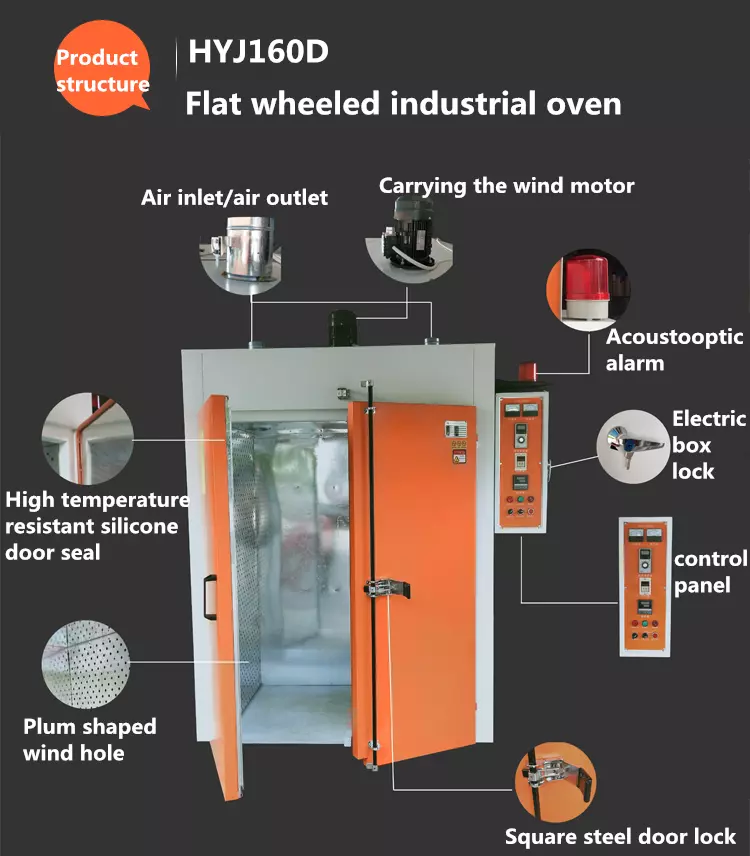

Detailed understanding of fixed oven configuration, each section described in detailed.

The fixed oven is placed in a small cart, and the product only needs to be placed on the platform of the trolley to dry the product.

High temperature oven seals ensure a balanced temperature inside the oven. No loss of heat.

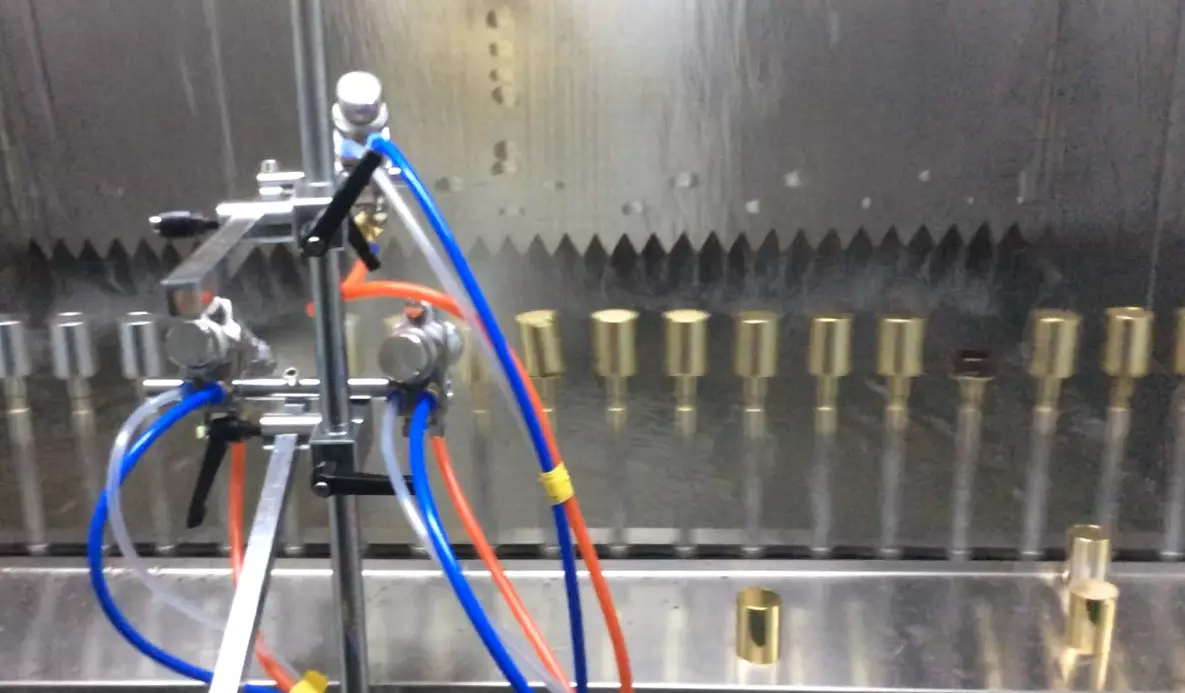

High temperature oven is suitable for glass, metal and ceramic products surface spray curing.

Main features

1) Sample structure, linear, easy to install and maitain.

2) Use quality stabilizing components, including pneumatic components, electrical components and operating components.

3) Insulation cotton thickness of 100mm/150mm, insulation cotton is fireproof material, high temperature resistant.

Related products

Small automatic spray painting machine

91.8% Response Rate

Small automatic UV curing machine

91.8% Response Rate

Big automatic UV spray painting line

91.8% Response Rate

Company FAQ

1) Q:Are you a factory or a trading company?

A:We are factory manufacture of pringting machine and we provide perfect OEM and after-sale service.

2) Q:How can I know your machine works well?

A:Before delivery,we shall test the machine working condition for you.

Company information

Categories: Fixed curing oven

Business type:Manufacturer

Certification:ISO9001,ISO14001,GB,CE,MSDS,UL,TUVOEM service:yes

Our Products Range