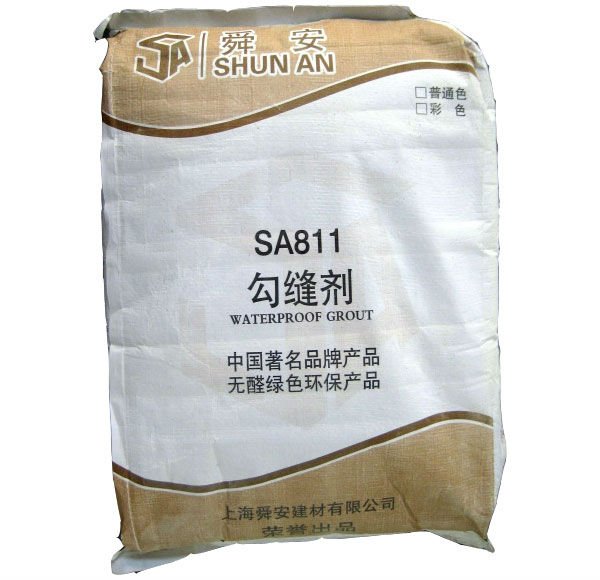

SA Dry Mix Cement -based Interior and Exterior Ceramic Tile Grout

| Unit Price: | Get Latest Price |

|---|---|

| Delivery Time: | 5 Days |

- Product Catalog

- Company List

Product Description

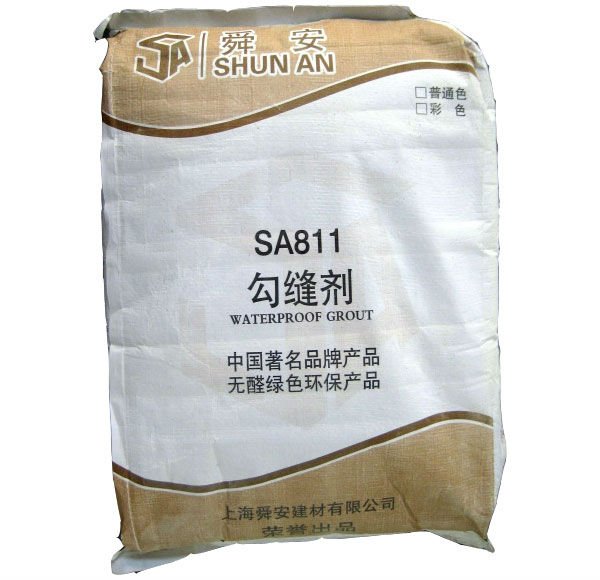

- Model No.: SA811

- Packaging: Packed in 25kg plastic lined paper sacks

- Brand Name: SA

- Place of Origin: Shanghai, China (Mainland)

Specifications 1)fill jonts from 1/8" to 1/3"

2)polymer-modified-just add water

3)creamy,easy to spread

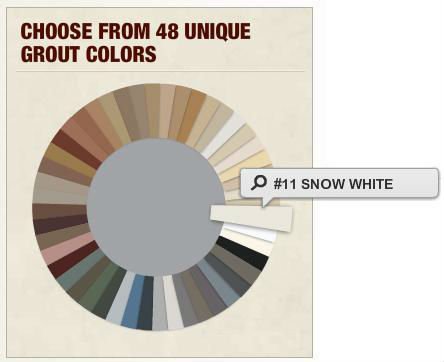

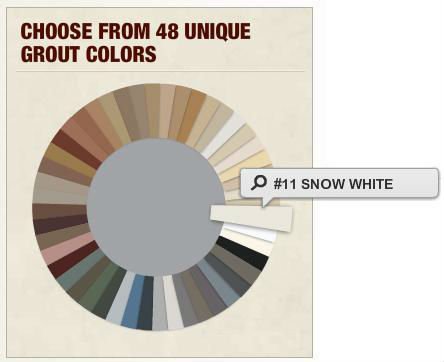

4)colors to complement today's tile

Tile fixing > Products > Grouts > color fill with sand SA wall & floor grouts are suitable for filling all wall and floor tile joints up to a width of 8mm. Available in a variety of colours, they are designed to inhibit moisture ingress and prevent bacterial and fungal growth. Extra Fine wall grout for a finer smooth and fine finish, when cured it is water resistant and suitable for internal and Suitable for joints between ceramic wall tiles up to 3mm can be use internal and external use. Also Suitable for use in wet areas including swimming pools and for use in kitchens and bathrooms. Product information

Color Plate Packaging · Weight: 25kg · Color: mutilcolor · Standard: JC/T 1004-2006 · Best before in months: 6 months · Storage: unopened bag on plate in dry and air spaces · Production date & batch number: Find on outside of bag Color colorful Field of application 1)Colored grout for tile joints from 3mm to 8mm wide on wall and floor 2)Suitable for grouting ceramic tiles, marble, stones etc. Limit of use Not suitable for area where there is strong acid corruption Consumption Typcially one 25 kg bag will cover 9-12.5 square meters (2-3 kg/m2 Consumption =(A+B)*C*D*1.5/(A*B) A- length of tile mm B- width of tile mm C- thickness of tile mm D- joint width mm PS: This formula does not include application wastage Application properties Joints width: 3~8mm (with sand) Application temperature: +5°C to +35°C Pot life: 2 hours Water addition: 0.23 liter/ kg powder Setting time: 24 hours Tools Rubber trowel,Trowel,Sponge,Bucket Substrate requirement The substrate should be hard, sound, dry, flat, clean and durable Substrate preparation · Ensure 24 hours of time interval after tiling · Before grouting, make sure that the tiles joints are clean without water Safety · May cause serious damage to eyes · May be sensitive to skin in case of contact. lrritable for eyes, respiratory system and skin · Keep out of the reach of children · Avoid breathing the dust · In case of contact with eyes,rinse eyes immediately with plenty of water and consult a doctor · Wear suitable protective clothing,gloves and eye / face protection Physical and Chemical Properties:

Color Plate Packaging · Weight: 25kg · Color: mutilcolor · Standard: JC/T 1004-2006 · Best before in months: 6 months · Storage: unopened bag on plate in dry and air spaces · Production date & batch number: Find on outside of bag Color colorful Field of application 1)Colored grout for tile joints from 3mm to 8mm wide on wall and floor 2)Suitable for grouting ceramic tiles, marble, stones etc. Limit of use Not suitable for area where there is strong acid corruption Consumption Typcially one 25 kg bag will cover 9-12.5 square meters (2-3 kg/m2 Consumption =(A+B)*C*D*1.5/(A*B) A- length of tile mm B- width of tile mm C- thickness of tile mm D- joint width mm PS: This formula does not include application wastage Application properties Joints width: 3~8mm (with sand) Application temperature: +5°C to +35°C Pot life: 2 hours Water addition: 0.23 liter/ kg powder Setting time: 24 hours Tools Rubber trowel,Trowel,Sponge,Bucket Substrate requirement The substrate should be hard, sound, dry, flat, clean and durable Substrate preparation · Ensure 24 hours of time interval after tiling · Before grouting, make sure that the tiles joints are clean without water Safety · May cause serious damage to eyes · May be sensitive to skin in case of contact. lrritable for eyes, respiratory system and skin · Keep out of the reach of children · Avoid breathing the dust · In case of contact with eyes,rinse eyes immediately with plenty of water and consult a doctor · Wear suitable protective clothing,gloves and eye / face protection Physical and Chemical Properties:

TILE WORK

2)polymer-modified-just add water

3)creamy,easy to spread

4)colors to complement today's tile

Tile fixing > Products > Grouts > color fill with sand SA wall & floor grouts are suitable for filling all wall and floor tile joints up to a width of 8mm. Available in a variety of colours, they are designed to inhibit moisture ingress and prevent bacterial and fungal growth. Extra Fine wall grout for a finer smooth and fine finish, when cured it is water resistant and suitable for internal and Suitable for joints between ceramic wall tiles up to 3mm can be use internal and external use. Also Suitable for use in wet areas including swimming pools and for use in kitchens and bathrooms. Product information

Color Plate Packaging · Weight: 25kg · Color: mutilcolor · Standard: JC/T 1004-2006 · Best before in months: 6 months · Storage: unopened bag on plate in dry and air spaces · Production date & batch number: Find on outside of bag Color colorful Field of application 1)Colored grout for tile joints from 3mm to 8mm wide on wall and floor 2)Suitable for grouting ceramic tiles, marble, stones etc. Limit of use Not suitable for area where there is strong acid corruption Consumption Typcially one 25 kg bag will cover 9-12.5 square meters (2-3 kg/m2 Consumption =(A+B)*C*D*1.5/(A*B) A- length of tile mm B- width of tile mm C- thickness of tile mm D- joint width mm PS: This formula does not include application wastage Application properties Joints width: 3~8mm (with sand) Application temperature: +5°C to +35°C Pot life: 2 hours Water addition: 0.23 liter/ kg powder Setting time: 24 hours Tools Rubber trowel,Trowel,Sponge,Bucket Substrate requirement The substrate should be hard, sound, dry, flat, clean and durable Substrate preparation · Ensure 24 hours of time interval after tiling · Before grouting, make sure that the tiles joints are clean without water Safety · May cause serious damage to eyes · May be sensitive to skin in case of contact. lrritable for eyes, respiratory system and skin · Keep out of the reach of children · Avoid breathing the dust · In case of contact with eyes,rinse eyes immediately with plenty of water and consult a doctor · Wear suitable protective clothing,gloves and eye / face protection Physical and Chemical Properties:

Color Plate Packaging · Weight: 25kg · Color: mutilcolor · Standard: JC/T 1004-2006 · Best before in months: 6 months · Storage: unopened bag on plate in dry and air spaces · Production date & batch number: Find on outside of bag Color colorful Field of application 1)Colored grout for tile joints from 3mm to 8mm wide on wall and floor 2)Suitable for grouting ceramic tiles, marble, stones etc. Limit of use Not suitable for area where there is strong acid corruption Consumption Typcially one 25 kg bag will cover 9-12.5 square meters (2-3 kg/m2 Consumption =(A+B)*C*D*1.5/(A*B) A- length of tile mm B- width of tile mm C- thickness of tile mm D- joint width mm PS: This formula does not include application wastage Application properties Joints width: 3~8mm (with sand) Application temperature: +5°C to +35°C Pot life: 2 hours Water addition: 0.23 liter/ kg powder Setting time: 24 hours Tools Rubber trowel,Trowel,Sponge,Bucket Substrate requirement The substrate should be hard, sound, dry, flat, clean and durable Substrate preparation · Ensure 24 hours of time interval after tiling · Before grouting, make sure that the tiles joints are clean without water Safety · May cause serious damage to eyes · May be sensitive to skin in case of contact. lrritable for eyes, respiratory system and skin · Keep out of the reach of children · Avoid breathing the dust · In case of contact with eyes,rinse eyes immediately with plenty of water and consult a doctor · Wear suitable protective clothing,gloves and eye / face protection Physical and Chemical Properties: Items | Data | |

Abrasion resistance | < 2000 mm3 | |

Shrinkage | < 3,0 mm/m | |

Flexural strength | standard experimental condition | >2,50 N/mm2 |

after freeze-thaw cycles | > 2,50 N/mm2 | |

Compressive strength | standard experimental condition | > 15,0 N/mm2 |

after freeze-thaw cycles | > 15,0 N/mm2 | |

Water absorption | 30 min | < 5,0 g |

4 hours | < 10,0 g | |

Related Keywords

Shanghai Shunan Building Material CO.,LTD is a construction company and building materials manufacturer.

The EIFS products produced in Shunan are:

1) Dry-mix mortar

- Brick-laying mortar

- Tile adhesives and joints grouts

- Wall renders and plasters ( interior and exterior)

- Floor screeds, self-levelling underlayments and skim coats

- External Insulation and Finishing Systems (EIFS) products

- Powder paints

- Patching and repair mortars

2) Thermal Insulation Panels And Fireproof Board

- Polyurethane/polyisocyanate composite board, pre-insulated air duct panel alu foil covered, freezer panel

- Polyestyrene foam insulation sheets(Extruded Polystyrene Insulation and Expanded Polystyrene Insulation), EPS/XPS sandwich panels, thermo-acoustic insulation layer from extruded polystyrene

- Rockwool insulation board

- Cellular glass boards

3) Accessories and supplementary of EIFS

- Fiberglass mesh & fiber glass mesh self - adhesive

- EIFS plastic dowels

- Corner bead

4)Concrete Admixtures

- Concrete/mortar accelerator

- SNF

- Expansion agent (sy-a,sy-k,sy-g)

- High performance water reducing agent

5)Base coat( bottom coating)/Top Coating

- Heavy Textured Acrylic Primer

- Heavy Textured Acrylic Finish Coat

6)Waterproofing materials

- Polyurethane waterproofing coating

- Waterproof Membrane

The product of the company has the following characteristics

1) Environmentally friendly and healthy, we have obtained ISO 9001 2008

2) The quality is stable and excellent

3) A variety of products, satisfies all the needs of old building and new building.

4) Effective construction, can be implemented both mechanically and manually, increases effectiveness from 250% to 800%, short working times with high efficiency.

5) A life time of cost efficiency, usage and maintenance costs are low.

6) Saves resources, can save up to 7% in the usage of basic building, saving can be up to 1.5% while reducing the investments for pegs, foundation walls, floors, cement, and reinforcing steel, and respectively reducing the usage of cement, concrete and reinforcing steel bars.

7) Simple to construct, the advanced integration enables the individual constructor to build without professional training, and build like one pleases.

Facade

SA Group has as early as 2004 begun to research and produce outer wall insulation system, and with the Facade external wall series it has already an experience of 8 years,The Facade external insulation system uses polystyrene foam boards or XPS boards as insulation material, with the boards pasted on the wall with Facade adhesive, and then fastened to the wall with fasteners. Afterwards two coats of adhesive are applied onto the boards with a glass fiber mesh embedded into the adhesive. Finally the surface is covered with a paint or decorative plaster, and so an external insulation system is achieved. This system offers a satisfactory insulation result and stands time and weather while at same time possesses a decorative impression. It is a versatile system for heat insulation in buildings. SA Groups Facade ETICS has the advantages listed below:

1) Upstanding adhesive capability. Ensures that the insulation boards are firmly applied on the walls.

2) Low water absorption. With the combination of the materials, the walls are water resistant and let rain water flow quickly off the surface of the wall, while keeping the insulation layer dry and obtain a favorable insulation effect.

3) Fiber reinforced crack preventive characteristic. The Facade adhesive for the external insulation system is equipped with polymer which also prevent cracking,

4) The flexibility of the materials. The adhesive used with the external heat insulation has to correspond with the flexibility of the insulation boards. The adhesives and plasters for the Facade external insulation system are added with polymers which correspond with the insulation boards, thus providing the Facade system to be wear and crack proof.

The EIFS products produced in Shunan are:

1) Dry-mix mortar

- Brick-laying mortar

- Tile adhesives and joints grouts

- Wall renders and plasters ( interior and exterior)

- Floor screeds, self-levelling underlayments and skim coats

- External Insulation and Finishing Systems (EIFS) products

- Powder paints

- Patching and repair mortars

2) Thermal Insulation Panels And Fireproof Board

- Polyurethane/polyisocyanate composite board, pre-insulated air duct panel alu foil covered, freezer panel

- Polyestyrene foam insulation sheets(Extruded Polystyrene Insulation and Expanded Polystyrene Insulation), EPS/XPS sandwich panels, thermo-acoustic insulation layer from extruded polystyrene

- Rockwool insulation board

- Cellular glass boards

3) Accessories and supplementary of EIFS

- Fiberglass mesh & fiber glass mesh self - adhesive

- EIFS plastic dowels

- Corner bead

4)Concrete Admixtures

- Concrete/mortar accelerator

- SNF

- Expansion agent (sy-a,sy-k,sy-g)

- High performance water reducing agent

5)Base coat( bottom coating)/Top Coating

- Heavy Textured Acrylic Primer

- Heavy Textured Acrylic Finish Coat

6)Waterproofing materials

- Polyurethane waterproofing coating

- Waterproof Membrane

The product of the company has the following characteristics

1) Environmentally friendly and healthy, we have obtained ISO 9001 2008

2) The quality is stable and excellent

3) A variety of products, satisfies all the needs of old building and new building.

4) Effective construction, can be implemented both mechanically and manually, increases effectiveness from 250% to 800%, short working times with high efficiency.

5) A life time of cost efficiency, usage and maintenance costs are low.

6) Saves resources, can save up to 7% in the usage of basic building, saving can be up to 1.5% while reducing the investments for pegs, foundation walls, floors, cement, and reinforcing steel, and respectively reducing the usage of cement, concrete and reinforcing steel bars.

7) Simple to construct, the advanced integration enables the individual constructor to build without professional training, and build like one pleases.

Facade

SA Group has as early as 2004 begun to research and produce outer wall insulation system, and with the Facade external wall series it has already an experience of 8 years,The Facade external insulation system uses polystyrene foam boards or XPS boards as insulation material, with the boards pasted on the wall with Facade adhesive, and then fastened to the wall with fasteners. Afterwards two coats of adhesive are applied onto the boards with a glass fiber mesh embedded into the adhesive. Finally the surface is covered with a paint or decorative plaster, and so an external insulation system is achieved. This system offers a satisfactory insulation result and stands time and weather while at same time possesses a decorative impression. It is a versatile system for heat insulation in buildings. SA Groups Facade ETICS has the advantages listed below:

1) Upstanding adhesive capability. Ensures that the insulation boards are firmly applied on the walls.

2) Low water absorption. With the combination of the materials, the walls are water resistant and let rain water flow quickly off the surface of the wall, while keeping the insulation layer dry and obtain a favorable insulation effect.

3) Fiber reinforced crack preventive characteristic. The Facade adhesive for the external insulation system is equipped with polymer which also prevent cracking,

4) The flexibility of the materials. The adhesive used with the external heat insulation has to correspond with the flexibility of the insulation boards. The adhesives and plasters for the Facade external insulation system are added with polymers which correspond with the insulation boards, thus providing the Facade system to be wear and crack proof.

Basic Information

- Company Name:

Shanghai Shun'an Building Materials Co.,Ltd.

- Product/Service:

insulation material , tile adhesive mortar , construction grout

- Capital (Million US $):

5 Million RMB

- Year Established:

2004

- Company Address:

No.68, Wanda Road, Lingang Wanxiang Industrial Park

Other products from this company More

Email to this supplier

Categories: Portland cement based tile grout(joint filler)

Our Products Range

All Products Renders and Plasters (interior and exterior)Dry Mortars For External Insulation Systems|--EIFS Adhesive|--EIFS Base Coat|--Wall Renders and Plasters|--Mortar Produced By Vitrify Micro Beads Material|--OtherTile Adhesives & Joint Grouts|--SA tile adhesive range|--Portland cement based tile grout(joint filler)|--OtherSpecial Dry-mixed MortarWaterproofing cementitious|--Rapid Plug|--Admixtures for Mortars and Concrete|--Rapid Set Cement|--Waterproofing Mortar|--OtherInsulation Boards|--HVAC Systems & Parts|--Rockwool insulation|--Fiber composite plate|--OtherEIFS Accessories and Supplementary Items|--Fasteners|--Fiberglass Mesh|--OtherEIFS Finish CoatUngrouped