Double-layer steel strip flaking machine

| Unit Price: | USD 57800 - 58000 / Set/Sets |

|---|---|

| Transportation: | Ocean |

| Port: | shanghai |

- Product Catalog

- Company List

Product Description

- Model No.: RDJP150

- place of origin: China

- status: New

- Showroom location (in which countries are there sample rooms overseas): None

- Video factory inspection: Provided

- Mechanical test report: Provided

- Marketing type: Ordinary Product

- Core component warranty period: 1 Year

- warranty period: 1 Year

- Out-of-warranty service: Video Technical Support, Spare Parts, Field Maintenance And Repair Service

- Where to provide local services (in which countries are there overseas service outlets): None

- Applicable industry: Manufacturing Plant, Food &Amp; Beverage Shops, Other, Advertising Company

- Thickness:: 2-10 mm

- Material Quality:: 304,316,316L

- Model No.:: RDJP-150

- Packaging: Wooden Case

- Productivity: 1500-5000kg/h

- Brand Name: RUIDE

- Place of Origin: china

- Supply Ability: 10 set

- Certification: ISO9001

- HS Code: 8419899090

Overview:

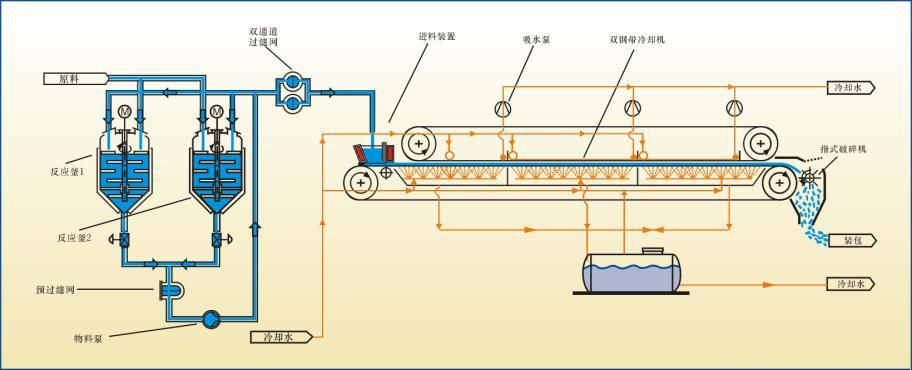

RDJP double-layer steel strip flaking machine takes advantage of the material's melting point below 300°C.According to the viscosity range of the material in the molten state, the melt is evenly distributed on the steel belt moving at a uniform speed under it through a special distribution device, and under the steel belt Under the cooling effect of the set continuous spray device, the materials can be cooled, solidified and packaged in the process of transportation and transportation, so as to achieve the purpose of granulation and molding.

This product is a new type (meltability) molding granulator. The work changes from liquid to solid through transportation and cooling, and the materials with melting point range of 50℃~300℃ can be granulated and formed. No dust, improved production environment; and has certain economic value (energy saving, economical packaging container), quick product replacement, beautiful granular products, uniform nearly hemispherical granular, no thermal stress; granular products are easy to package, transport and store , And it is convenient for users to measure, mix or remelt, and can produce continuously. From feeding to packaging, it reduces physical labor, has stepless speed regulation, adjustable flow rate, and convenient operation. It is widely used in petroleum, fine chemical and other industries. One machine can be used to make strips, cuts, and slices; toxic materials can be used for sealing groups.

china

Min. Order:1

china

Min. Order:1

china

Min. Order:1

china

Min. Order:1

china

Min. Order:1

Changzhou Ruide Drying Engineering Technology Co., Ltd. is a professional manufacturer of Melt granulator,drying, mixing, granulating and grinding equipment. Our firm has strong technical force and adopts CAD system, with a modern workshop. Our company is located in the economic center of Yangtze River Delta - Changzhou. Our company has a large-scale manufacturing site. The engineers and technicians account for more than 70% of total staff members. In accordance with the national GMP standard, Our company has a professional team with support from Tianji University, Dalian university of technology and many other famous universities. We keep up with the latest international development within our scope and advocate scientific orientation. Our company is possessed with excellent means of detection and advanced conception of management. We can meet the requirements of domestic and international customers. The production of our equipment conforms strictly to the ISO9001 international quality management system. Their successful application is in the scope of pharmaceutical,chemical, foodstuff industries and so on, which has achieved the internationalization of the product quality. The honest and practical conduct of enterprise, excellent product quality, precise follow-up maintenance service and excellent after-sale service have gained us market and credit.

Basic Information

- Company Name:

Changzhou Ruide Drying Engineering Technology Co., Ltd

- Representative:

Zhongxing Liu

- Business Type:

Manufacturer

- Product/Service:

Melt granulator , Steel strip bonding machine , Drying Equipment , Sieving Equipment , Mixing Equipment , Granulating Equipment

- No. of Total Employees:

5~50

- Capital (Million US $):

10,000,000RMB

- Year Established:

2015

- Product Range:

Other Lighters & Smoking Accessories , Mixing Equipment , Reactors

- Certificate:

Manufacturer

- Company Address:

Jiaoxi Town, Wujin District, Changzhou City, Jiangsu Province, China

Trade & Market

- Total Annual Sales Volume (Million US $):

US$1 Million - US$2.5 Million

- Export Percentage:

71% - 80%

- Total Annual Purchase Volume (Million US $):

Below US$1 Million

- Main Markets:

Americas , Asia , Europe , North Europe , West Europe , Other Markets

Factory Information

- No. of Production Lines:

3

- No. of R&D Staff:

5 -10 People

- No. of QC Staff:

Fewer than 5 People

- OEM Services Provided:

YES

- Factory Size (Sq.meters):

3,000-5,000 square meters

- Factory Location:

Jiaoxi Town, Wujin District, Changzhou City, Jiangsu Province

Other products from this company MoreEmail to this supplierCategories: Steel Strip Flaking Machine

Business type:Manufacturer

Certification:ISO9001OEM service:YES

Our Products Range

All Products Cases|--Food Engineering Industry|--Chemical Engineering Industry|--Pharmaceutical Engineering Industry|--Other Engineering IndustryDryer|--Spray Dryer|--Vibrating Fluid Bed Dryer|--Spin Flash Dryer|--Hot Air Circulating Oven|--Horizontal Fluidizing Dryer|--Vibrating Fluidizing Bed Dryer|--Hollow Paddle Dryer|--Vacuum Drying Oven|--Double Cone Vacuum Dryer|--Vacuum Rake Dryer|--Belt Dryer|--Continuous Plate Dryer|--The Vacuum Freeze Drier|--Waste Water Evaporator|--Freeze drying machine|--Steam heat exchanger|--Stainless steel pan|--HYG Series Rotating Barrel Dryer|--HG Series Drum Scraper DryerCooling equipment|--Melt Granulator|--Steel Strip Flaking Machine|--Roller Flaking MachineGranulator|--GF Series Dry Granulators|--Fluid Bed Granulator|--Revolving Extruder Granulating Machine|--Swaying Granulator|--Dry Roller Granulator|--High Speed Mixing GranulatorMixer|--Ribbon Mixer|--Double Screw Cone Mixer|--Three Dimensional Mixer|--Two Dimensional Mixer|--Dual Shaft Paddle MixerGrinder|--High Efficiency Universal Grinder|--Super Fine Grinder|--Melt Granulation MachineOven|--Hot Air Circulation Drying Oven|--GMP Medicine Drying Oven|--Tunnel Drying Oven|--Drying Oven Tray|--Door Lock Door Hinge Drying Equipment Accessories|--Drying Oven Axial FanScreening equipment|--Round Vibrating Sieve|--Square Vibrating SieveDust removal equipmentHot Air FurnaceLoading equipmentTernary Material Reactor|--Negative Pressure Conveying SystemDustless Feeding System|--Pouch Feeding Station|--Tons Of Bag Unloading StationsAuxiliary Equipment|--Tons Of Bag Unpacking Machine|--Small Bag Automatic Unpacking MachinePackaging System|--Ton Bag Packaging System|--Box And Barrel Packaging SystemMask Machine|--Ultrasonic Welding MachineUltrasonic Lace MachineReaction Kettle